Our Product Categories

Explore our wide range of customizable bags designed to meet every corporate need.

Canvas Tote Bags

Premium heavy-duty cotton canvas tote bags perfect for corporate branding.

Non-Woven Bags

Cost-effective and durable polypropylene bags for large-scale events.

Jute Bags

Eco-friendly natural fiber bags with a rustic, premium appeal.

Insulated Cooler Bags

Thermal bags designed to keep items hot or cold. Ideal for food industry.

Gift Bags

Elegant bags designed for special occasions and premium gifting.

Zipper Pouches

Versatile small bags for cosmetics, tech accessories, or stationery.

How We Work

A streamlined production process ensuring quality and timely delivery for every order.

Consultation

We discuss your needs, budget, and timeline.

Bag Selection

Choose materials, styles, and dimensions.

Artwork & Branding

Submit your logo and approve the digital mockup.

Sampling

Receive a physical or photo sample for final approval.

"The quality of the bags exceeded our expectations. A true partner for our branding needs."

— Marketing Director, TechFlow Inc.

Why Corporate America Chooses BagWorks USA

We understand the high standards of U.S. businesses. From material selection to final delivery, we ensure your brand is represented with excellence.

Eco-Friendly Commitment

Sustainable materials including organic cotton, jute, and recycled non-woven fabrics.

Quality Assurance

Rigorous inspection at every stage. We guarantee the durability and print quality of every bag.

Reliable Logistics

Seamless nationwide delivery across the U.S. with transparent tracking and on-time arrival.

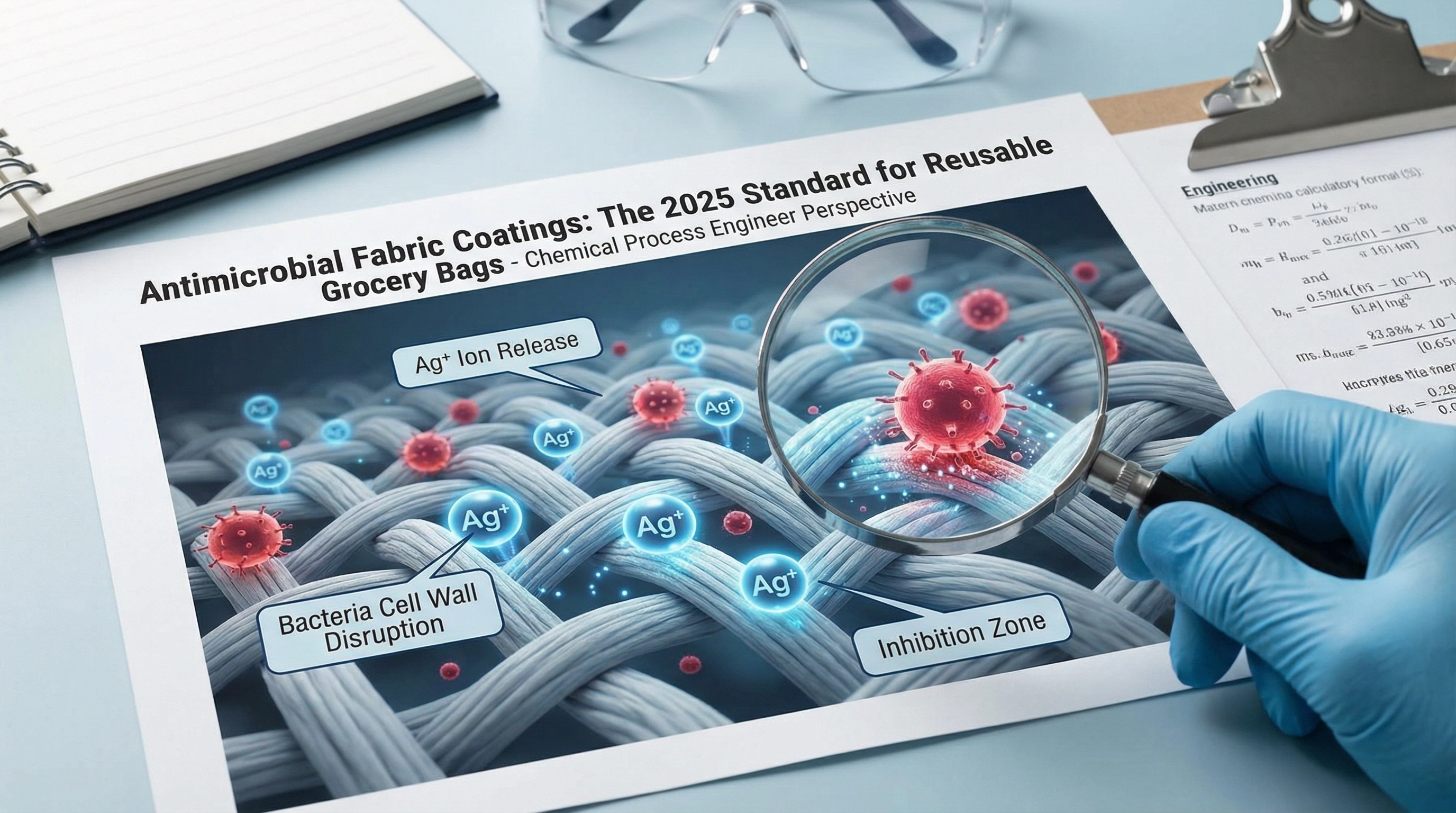

Antimicrobial Fabric Coatings: The 2025 Standard for Reusable Grocery Bags

A deep dive into the chemistry of silver-ion vs. silane-quat coatings and their efficacy in preventing cross-contamination in reusable grocery totes.

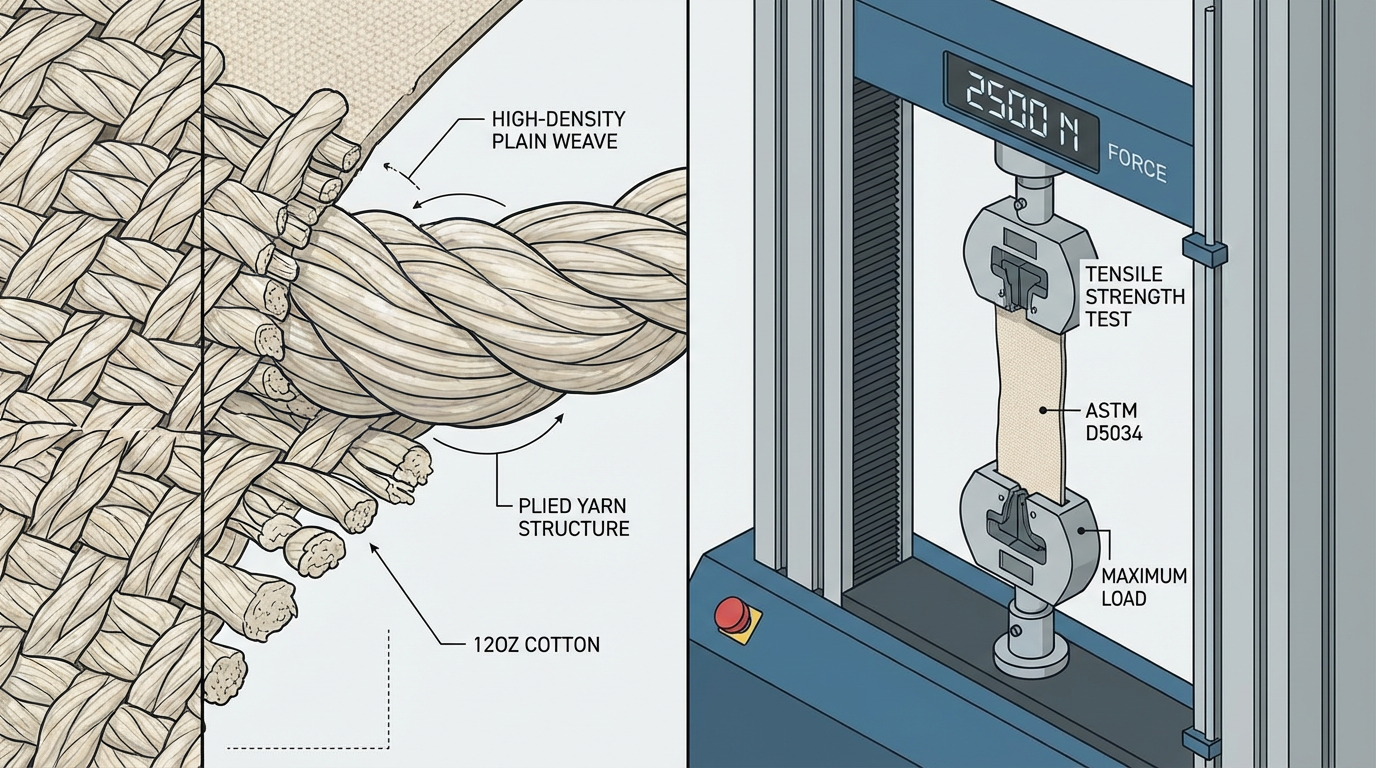

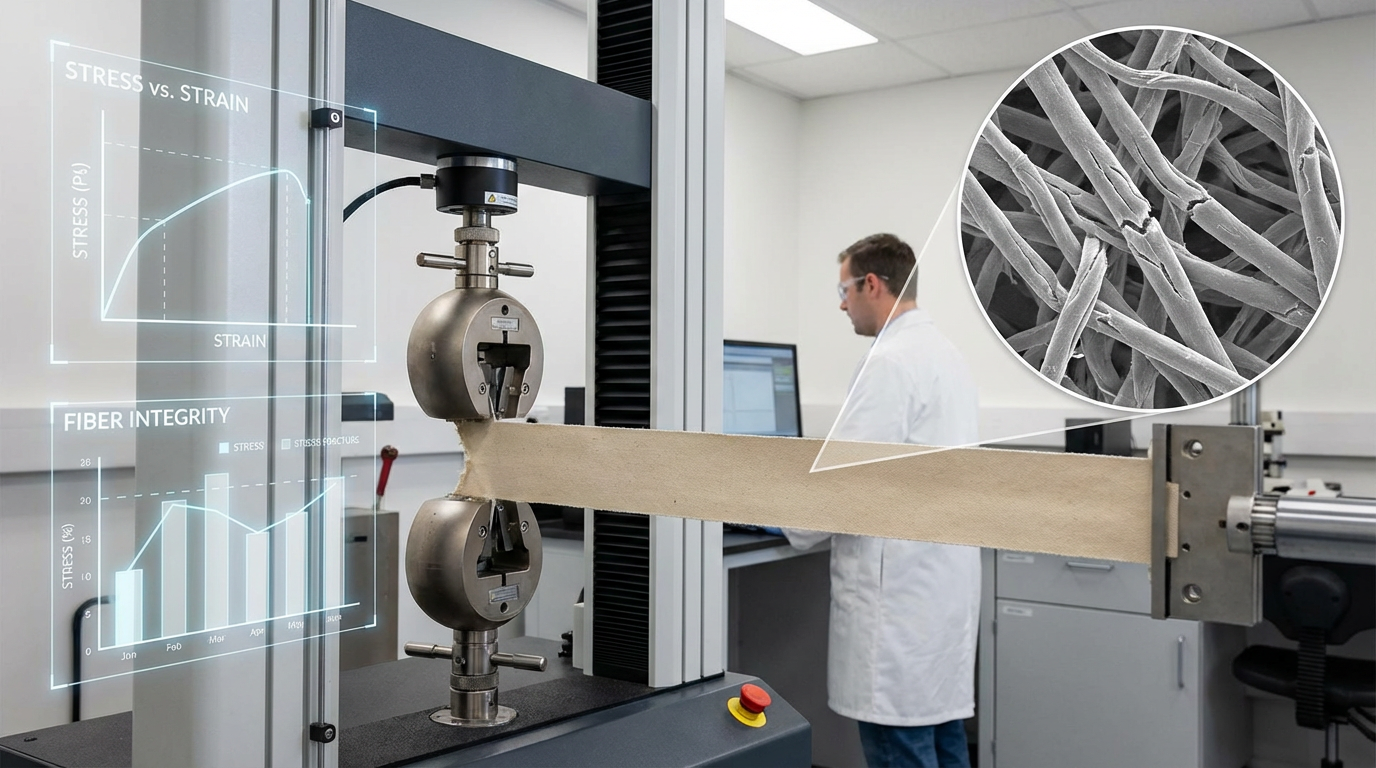

Recycled vs. Virgin Cotton: A Tensile Strength & Lifecycle Analysis

Quantifying the trade-offs: How short-fiber recycled cotton impacts load-bearing capacity and why blending ratios matter for industrial durability.

Nearshoring vs. Offshoring: A 2025 Cost-Benefit Analysis for US Brands

Is the premium for Mexico-based manufacturing worth the speed? Analyzing Total Landed Cost (TLC) models for Q1 2026 procurement planning.

Chicago Manufacturing Expo: Industrial Swag Trends for 2025

What the Midwest manufacturing sector demands: Heavy-duty, oil-resistant, and tool-ready reusable bags for the 2025 expo season.

Napa Valley Wine Industry: Sustainable Packaging Shifts for 2025

Moving beyond the wooden crate: Why Napa's top vineyards are adopting GOTS-certified organic cotton and jute wine totes for tasting room sales.

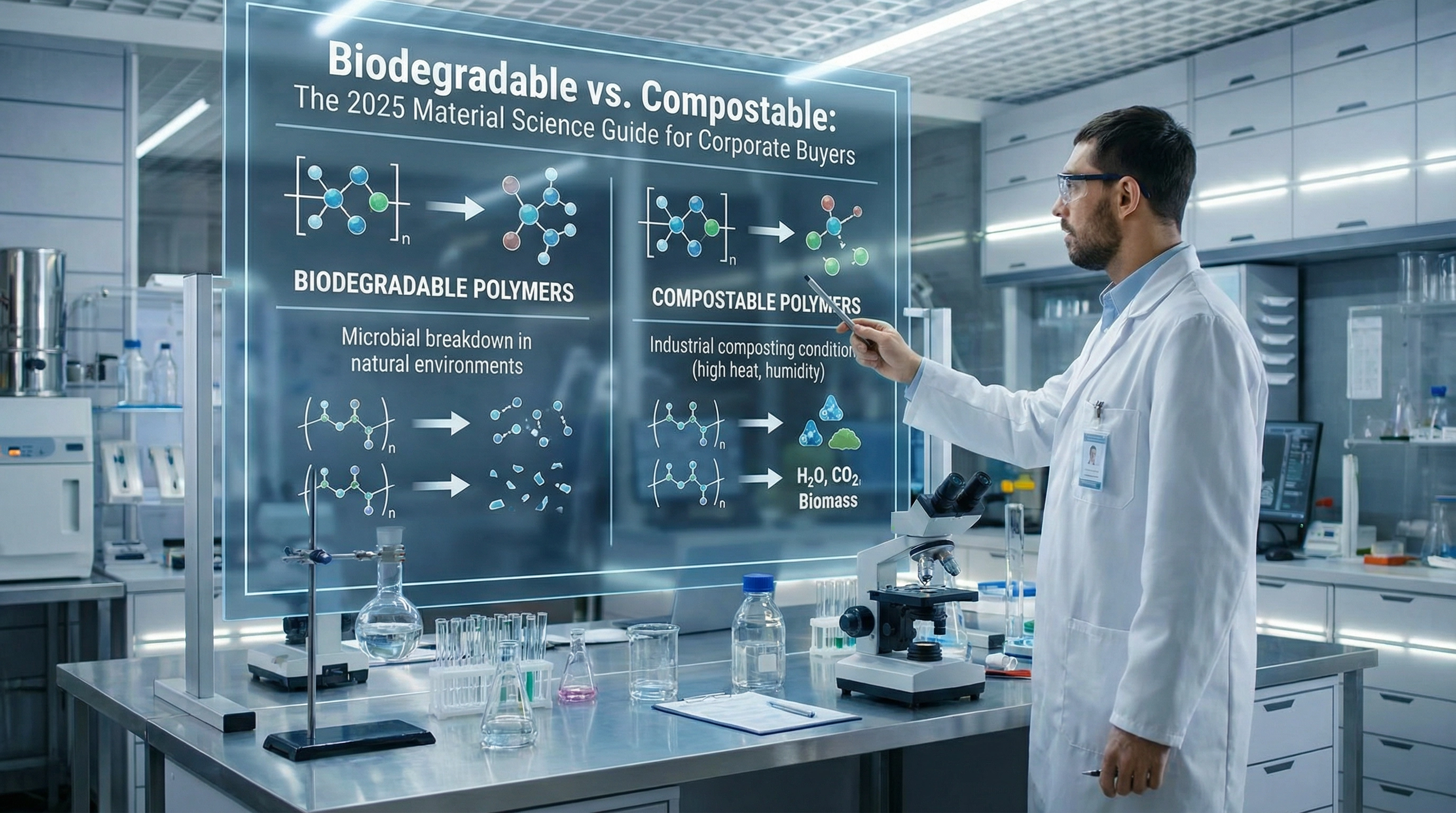

Biodegradable vs. Compostable: The 2025 Material Science Guide for Corporate Buyers

A technical breakdown of molecular degradation processes, ASTM standards, and the real-world lifecycle of sustainable bag materials.

The Physics of Load Bearing: Reinforced Stitching Patterns for Heavy Industrial Totes

Analyzing the stress distribution in Box-X vs. Double-Stitch patterns for industrial-grade reusable bags.

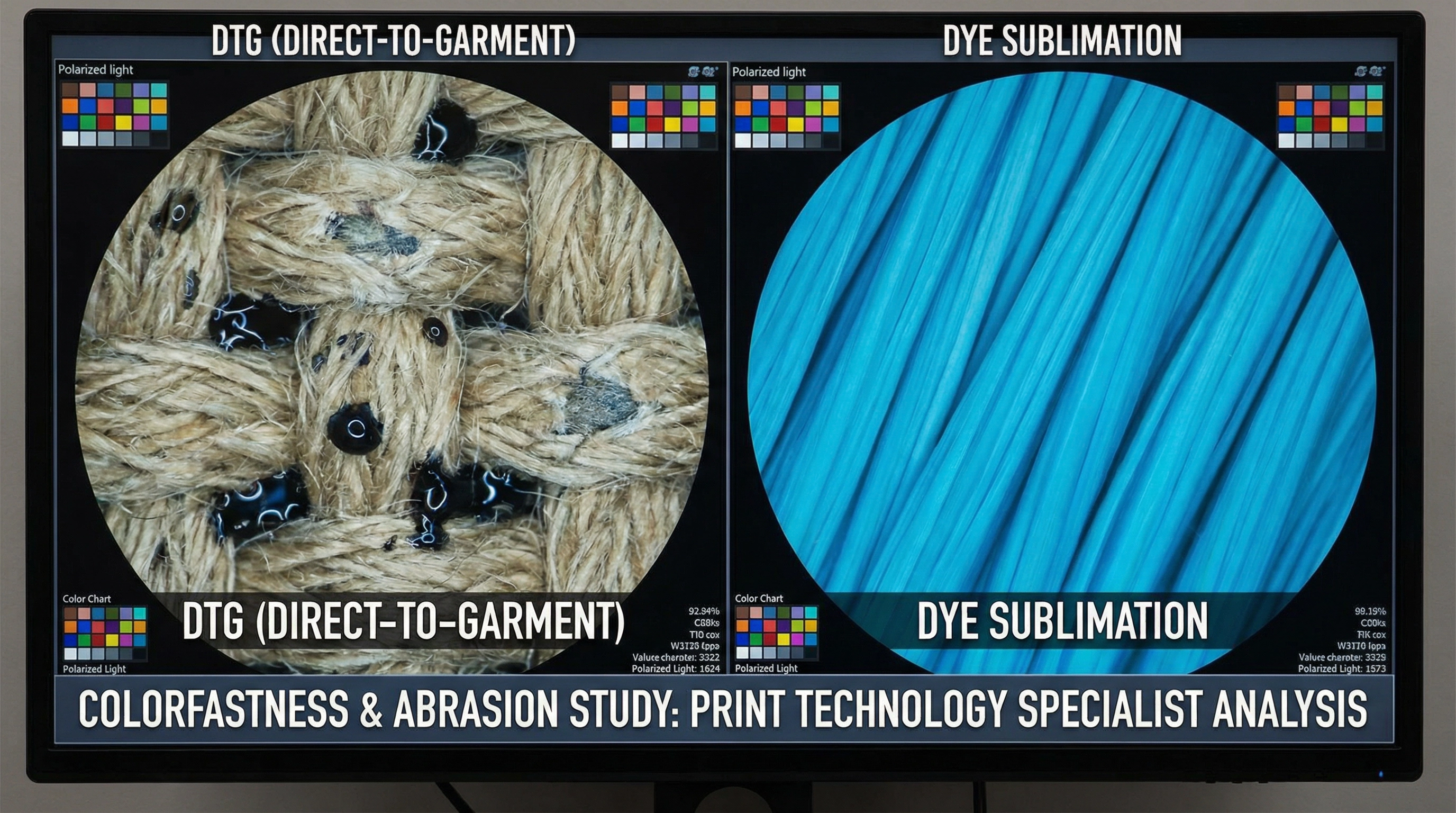

Digital Textile Printing (DTG) vs. Dye Sublimation: A Colorfastness & Abrasion Study

Comparing ink penetration depth and wash durability (ISO 105-C06) between direct-to-garment and sublimation on polyester blends.

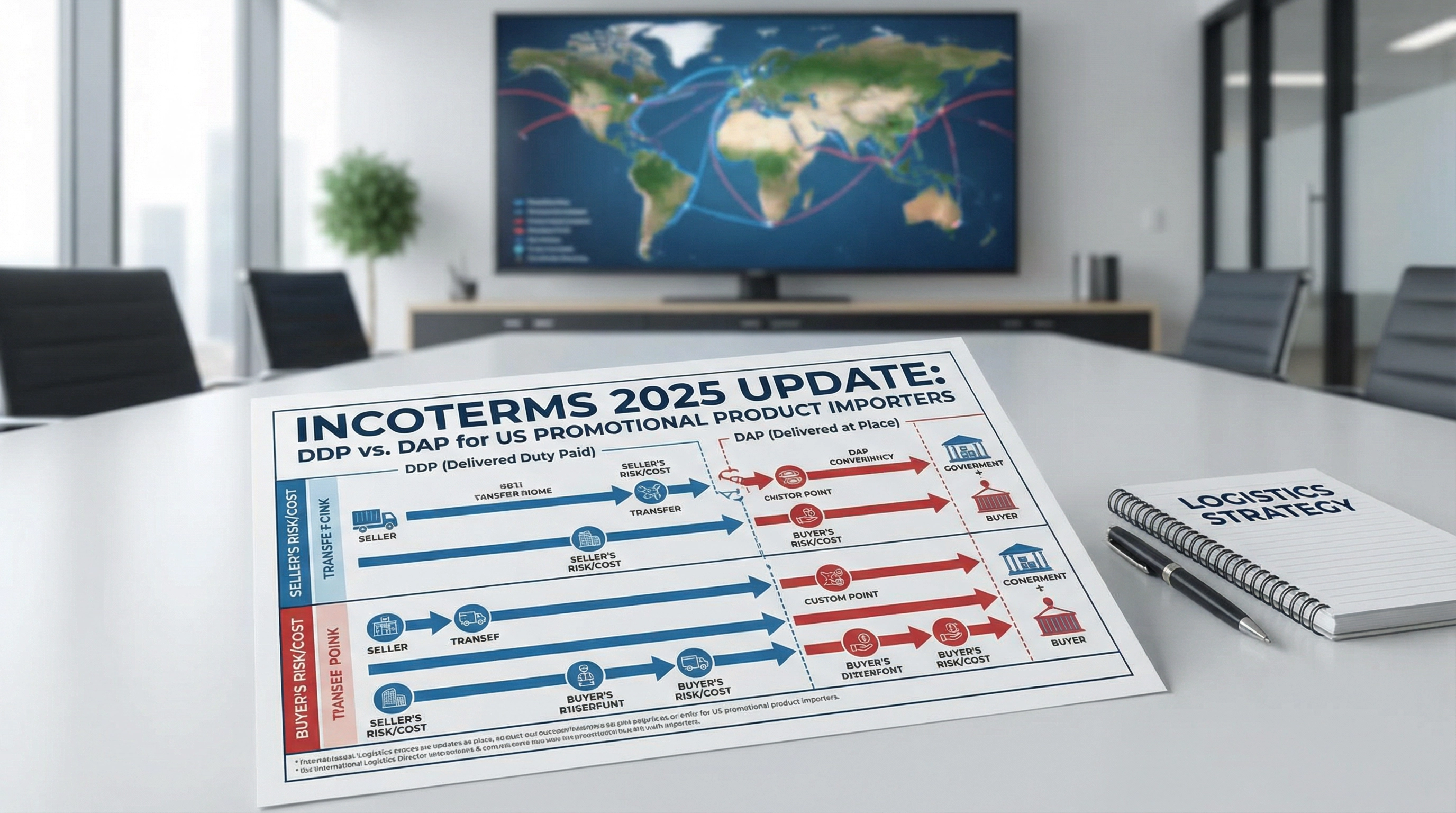

Incoterms 2025 Update: DDP vs. DAP for US Promotional Product Importers

Navigating the latest Incoterms updates and why DDP remains the safest bet for mid-sized corporate buyers in 2025.

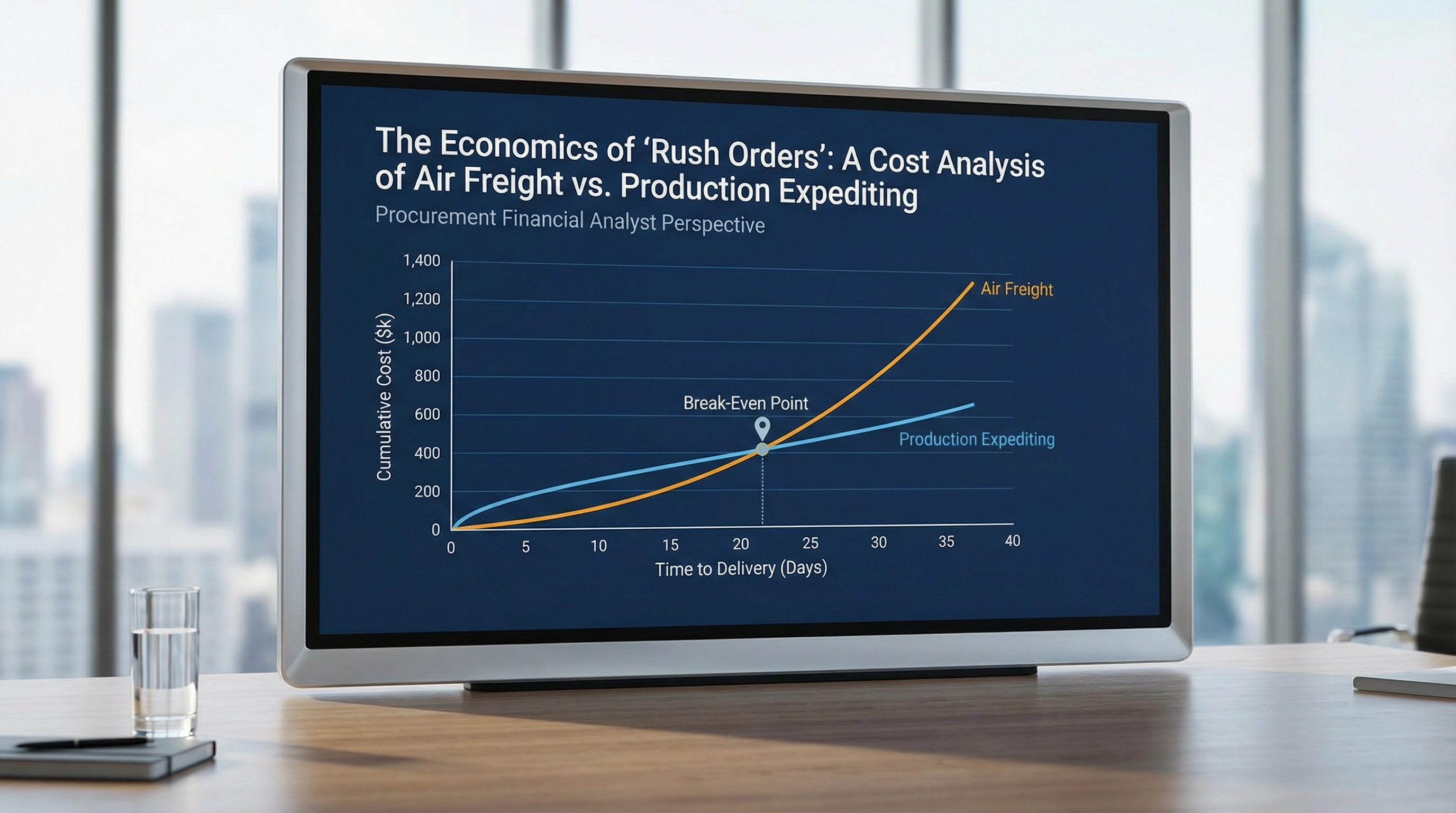

The Economics of 'Rush Orders': A Cost Analysis of Air Freight vs. Production Expediting

A quantitative look at where to spend your 'rush budget'—faster shipping or overtime production labor?

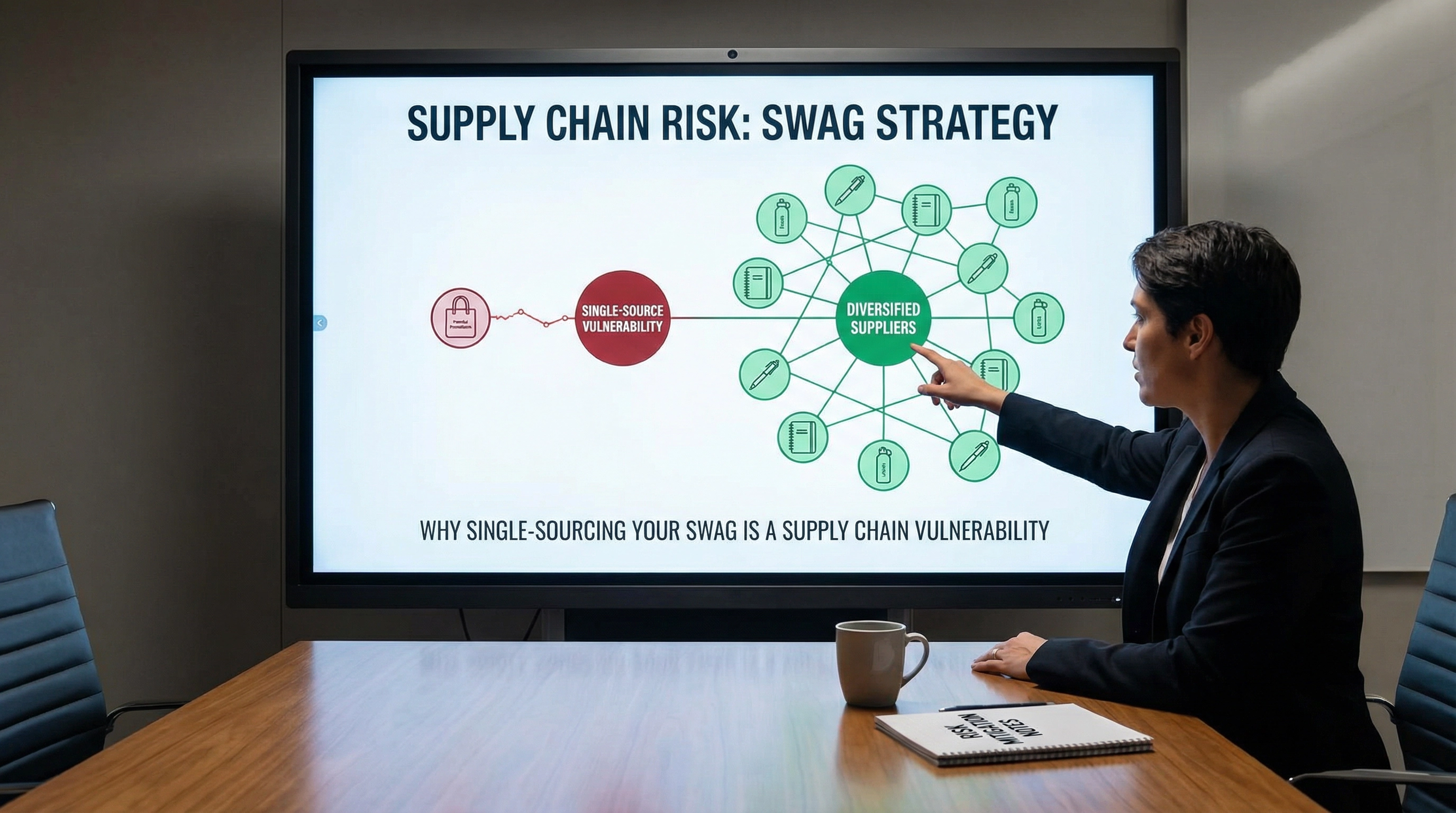

Vendor Consolidation Risks: Why Single-Sourcing Your Swag is a Supply Chain Vulnerability

Case studies of 2024 supply chain failures and why a multi-vendor strategy is critical for Q4 2025 security.

Austin Tech Scene: Sustainable Swag Trends for SXSW 2025

What the silicon hills are buying for 2025: A shift towards high-utility, locally-inspired, and tech-compatible reusable bags.

Miami Hospitality: Waterproof & Beach-Ready Branding for 2025 Resorts

Why Miami's top resorts are switching to high-end, water-resistant TPU and coated canvas totes for guest amenities.

Seattle Corporate Culture: The Rise of 'Rain-Proof' Commuter Bags

How Seattle's weather shapes employee gifting: The demand for waxed canvas and water-repellent commuter totes.

NYC Financial District: Premium Totes Replacing the Traditional Briefcase

The shift in Wall Street fashion: Why heavy canvas totes with leather accents are becoming the new standard for junior analysts and VPs alike.

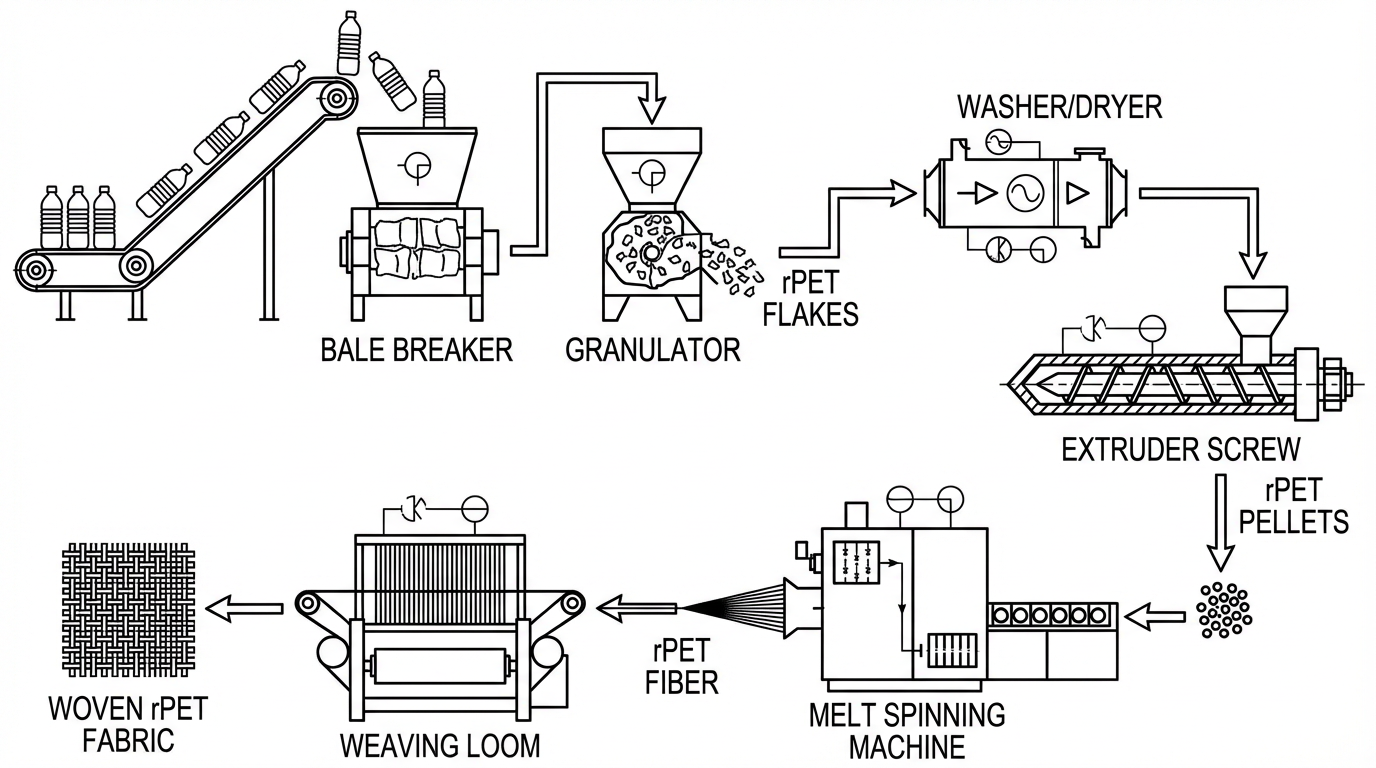

Comparative Analysis of rPET vs. Virgin Polyester in Heavy-Duty Industrial Bags

A deep dive into Comparative Analysis of rPET vs. Virgin Polyester in Heavy-Duty Industrial Bags from the perspective of a Material Engineer.

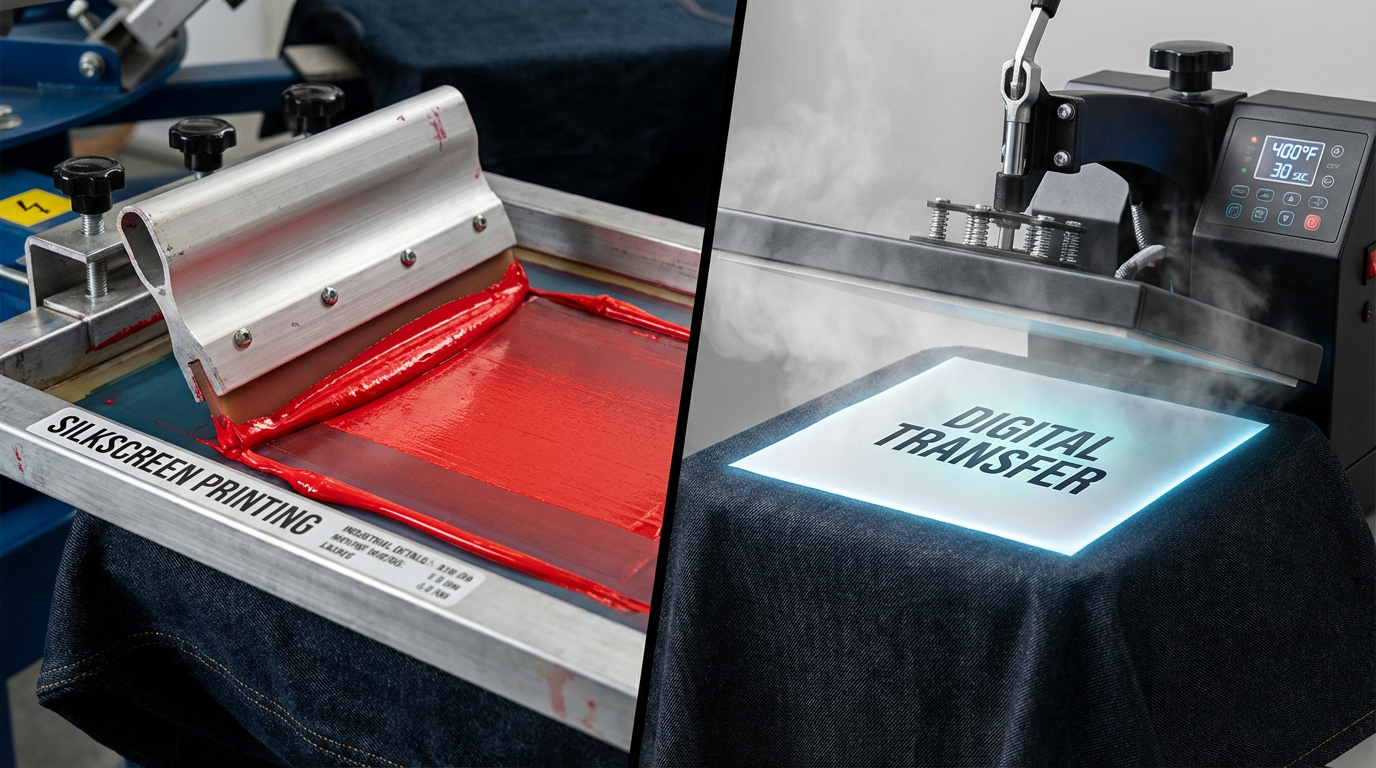

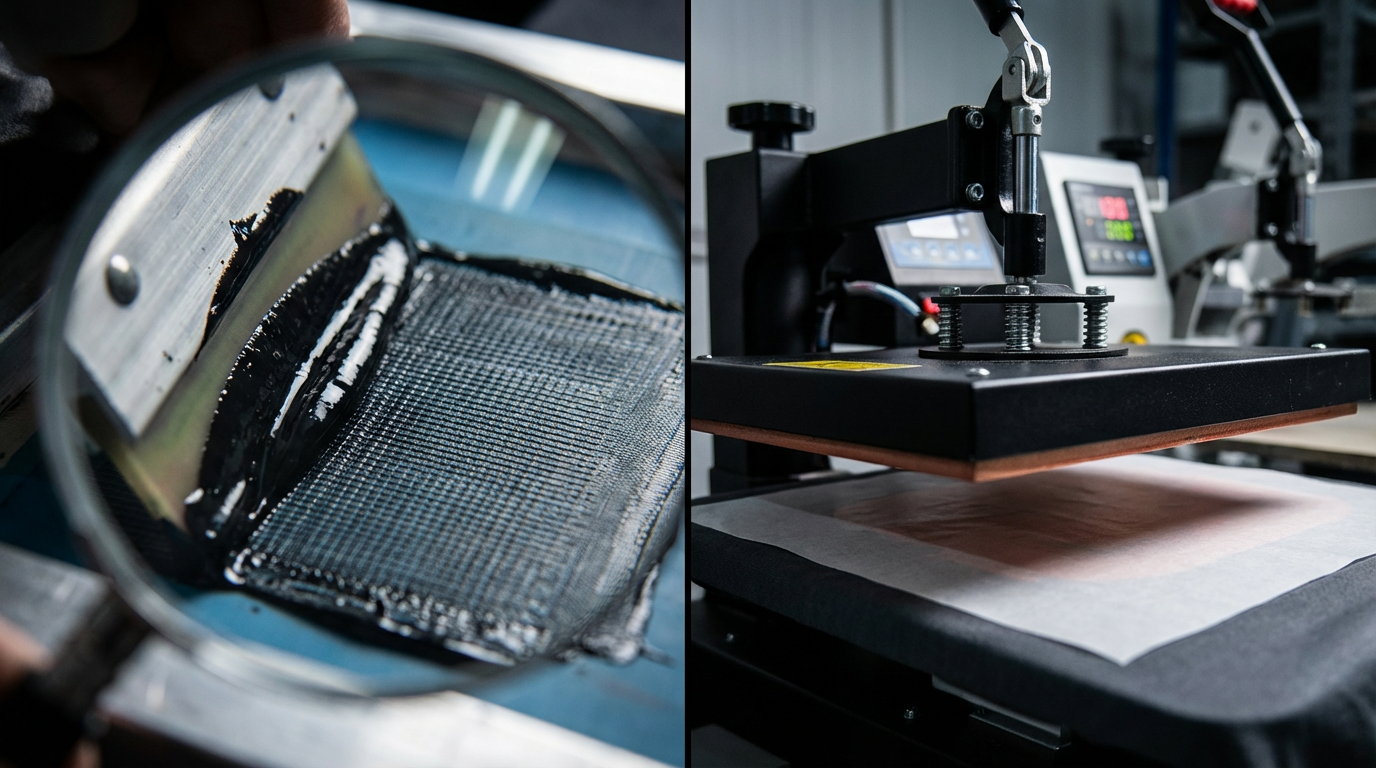

Screen Printing vs. Digital Heat Transfer: A Technical Durability Study for Corporate Logos

A deep dive into Screen Printing vs. Digital Heat Transfer: A Technical Durability Study for Corporate Logos from the perspective of a Printing Technology Specialist.

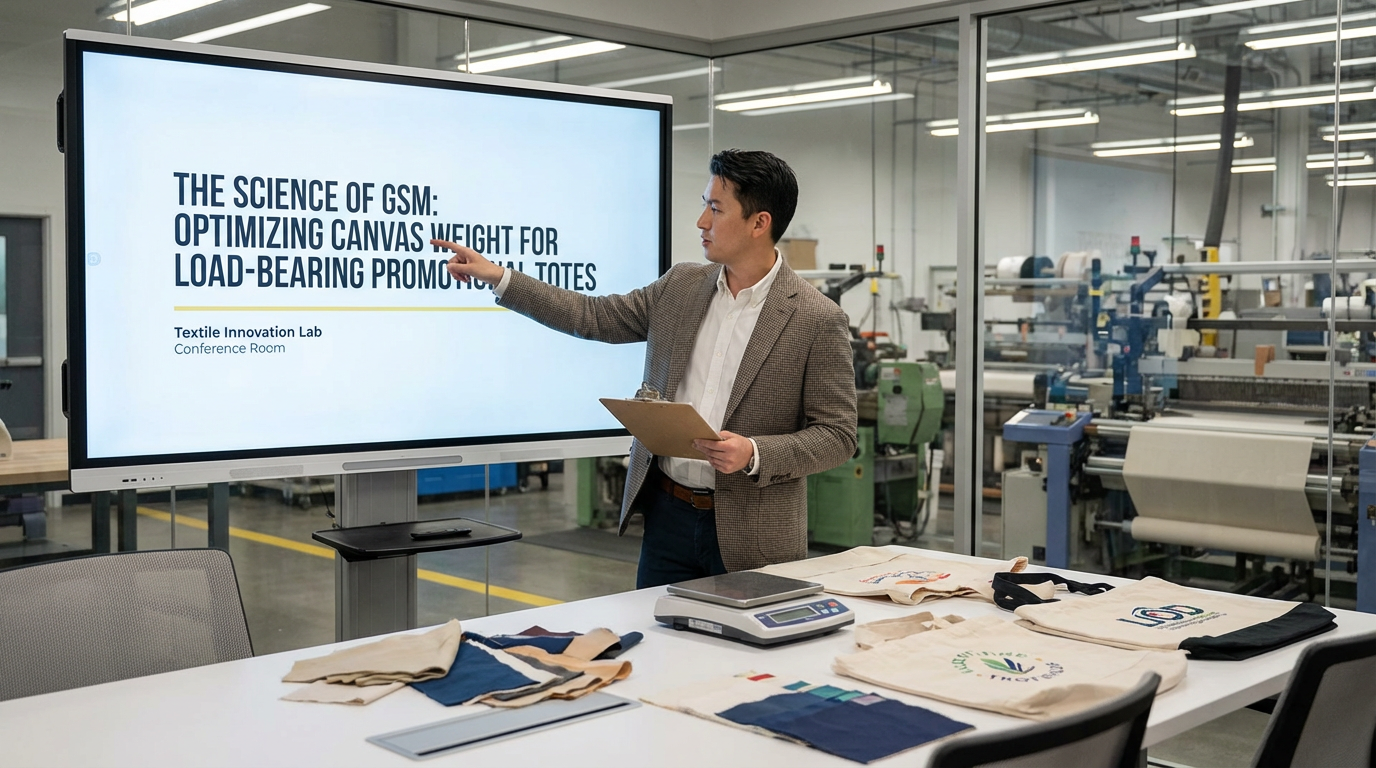

The Science of GSM: Optimizing Canvas Weight for Load-Bearing Promotional Totes

A deep dive into The Science of GSM: Optimizing Canvas Weight for Load-Bearing Promotional Totes from the perspective of a Textile Manufacturing Lead.

Navigating Supply Chain Volatility: Risk Mitigation Strategies for Q4 2025 Corporate Gifting

A deep dive into Navigating Supply Chain Volatility: Risk Mitigation Strategies for Q4 2025 Corporate Gifting from the perspective of a Supply Chain Risk Manager.

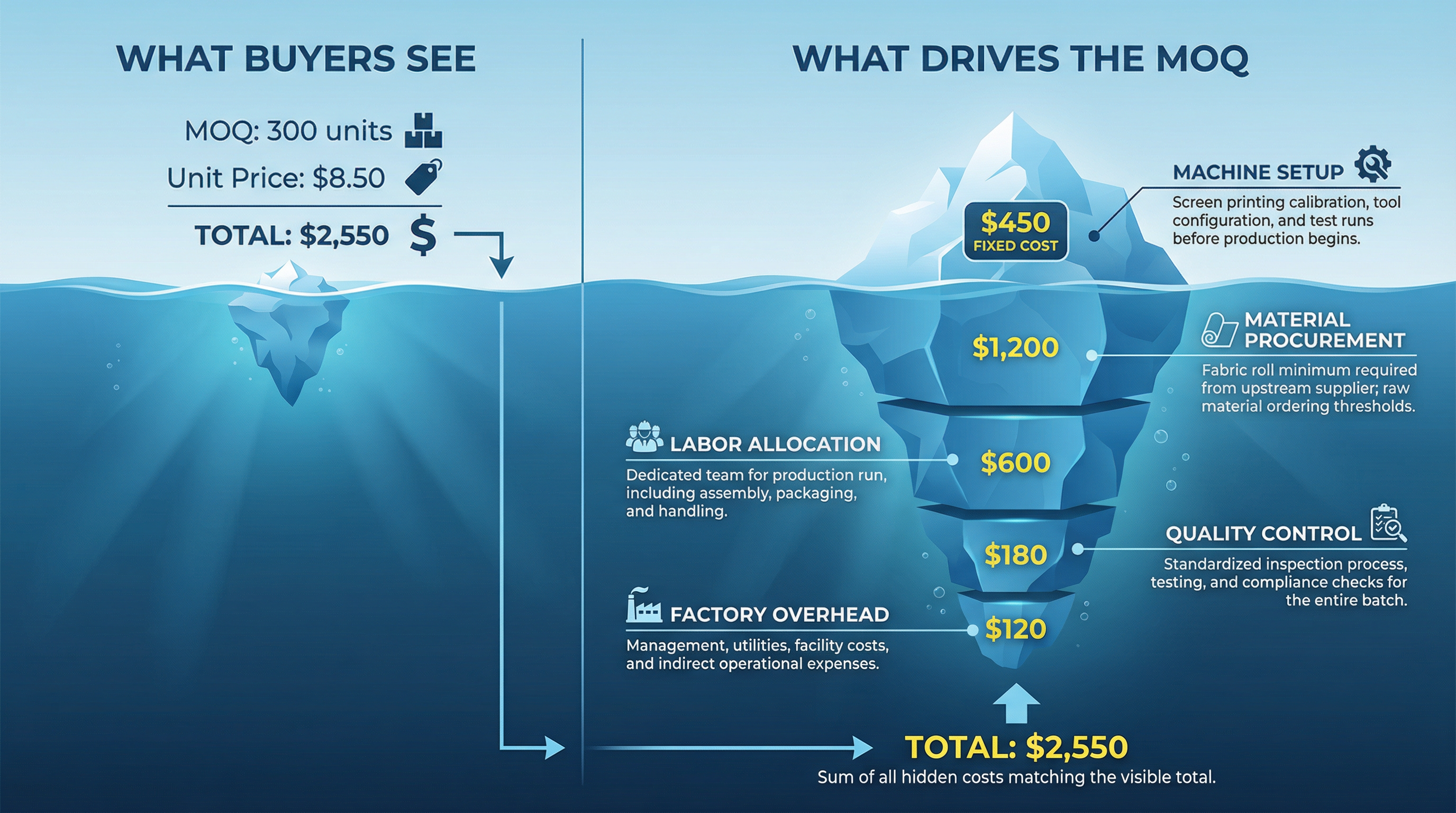

The Hidden Costs of Low MOQ: A Cost-Benefit Analysis for Enterprise Procurement

A deep dive into The Hidden Costs of Low MOQ: A Cost-Benefit Analysis for Enterprise Procurement from the perspective of a Senior Procurement Analyst.

Quality Control Protocols: Beyond the Visual Inspection for Custom Bag Orders

A deep dive into Quality Control Protocols: Beyond the Visual Inspection for Custom Bag Orders from the perspective of a QC Compliance Officer.

California SB 54 Compliance: What US Retailers Need to Know About Reusable Bag Standards in 2025

A deep dive into California SB 54 Compliance: What US Retailers Need to Know About Reusable Bag Standards in 2025 from the perspective of a Regulatory Compliance Consultant.

Tech Conference Swag Trends 2025: Data-Driven Insights from Silicon Valley Events

A deep dive into Tech Conference Swag Trends 2025: Data-Driven Insights from Silicon Valley Events from the perspective of a Event Marketing Strategist.

The Rise of 'Made in USA' vs. Ethically Sourced Imports: A 2025 Market Sentiment Analysis

A deep dive into The Rise of 'Made in USA' vs. Ethically Sourced Imports: A 2025 Market Sentiment Analysis from the perspective of a Market Research Analyst.

Sustainable Packaging in the Midwest: Manufacturing Sector Adoption Rates and Best Practices

A deep dive into Sustainable Packaging in the Midwest: Manufacturing Sector Adoption Rates and Best Practices from the perspective of a Industrial Sustainability Coordinator.

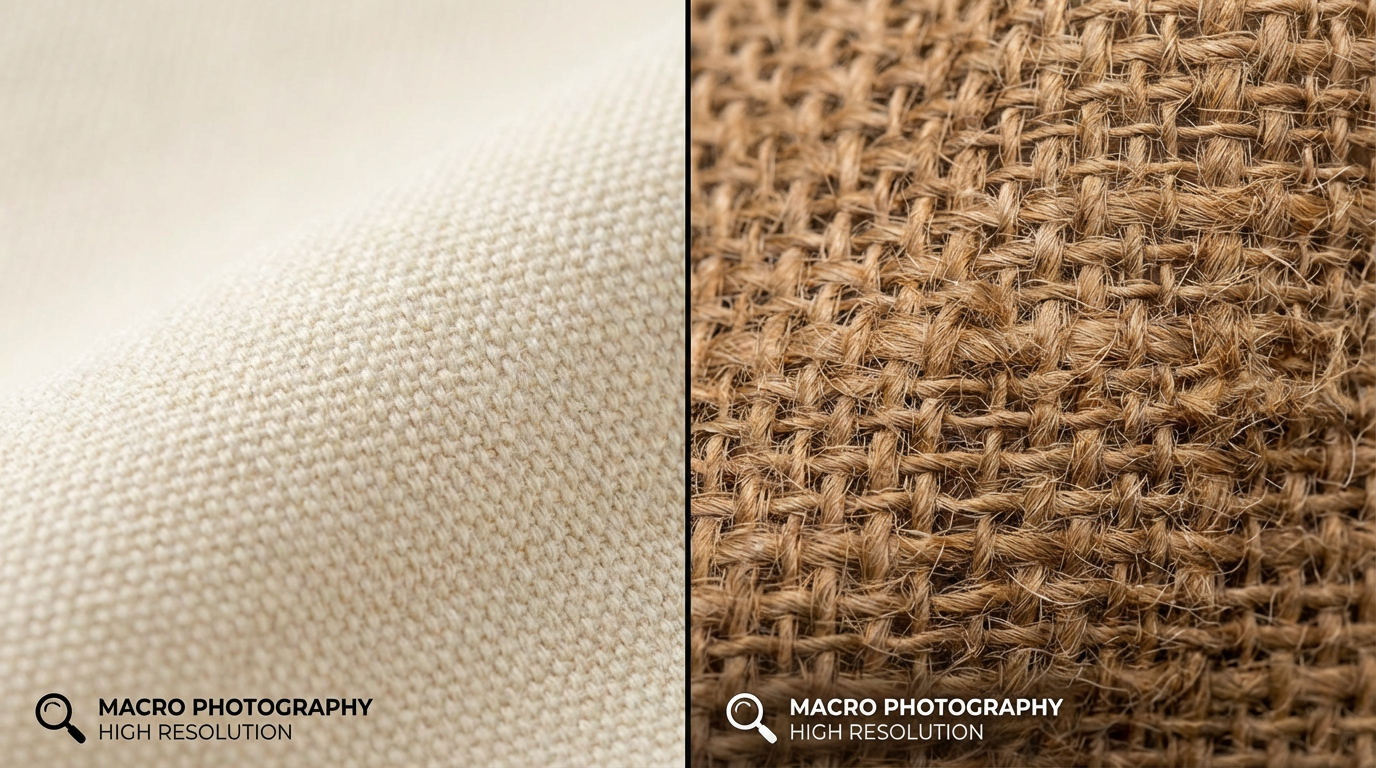

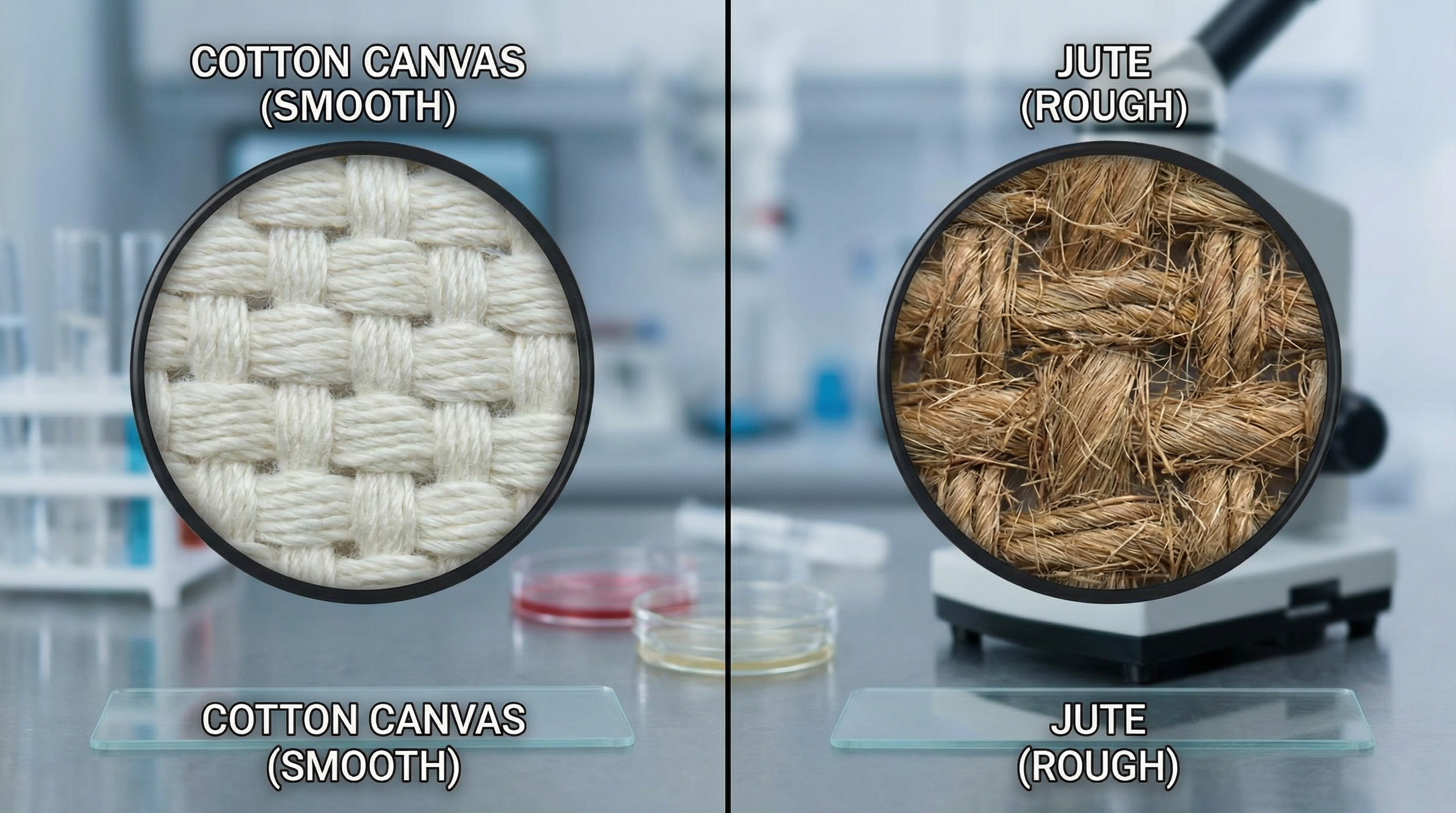

Canvas vs. Jute: Which Material Suits Your Corporate Brand?

A deep dive into the technical differences, durability, and eco-impact of canvas and jute bags to help you make the right choice for your next event.

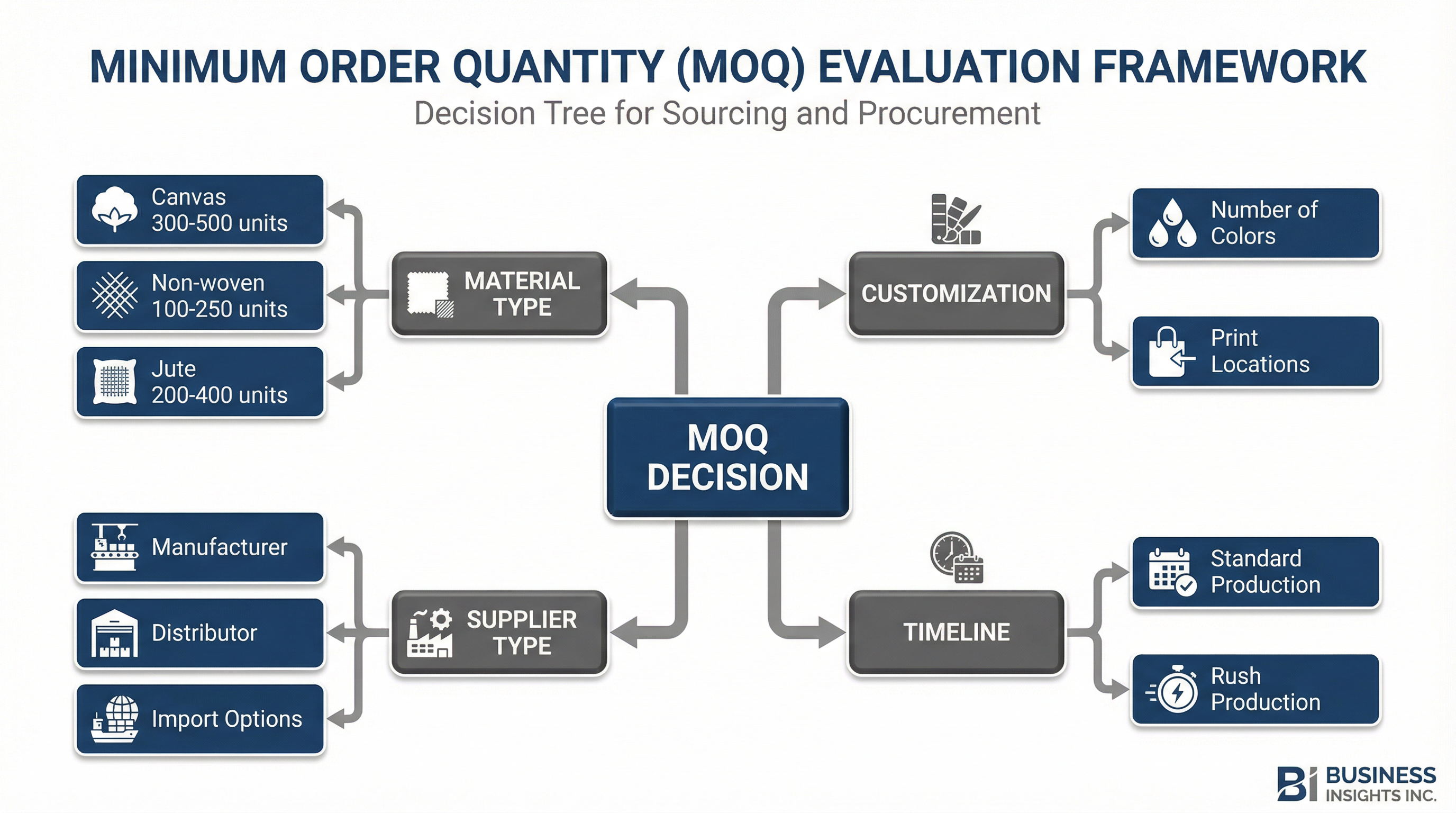

Navigating MOQ and Lead Times: A Supply Chain Manager's Guide

Understanding the balance between Minimum Order Quantities (MOQ) and production timelines to ensure your corporate event runs smoothly.

The Evolution of Corporate Gifting in the US: Trends for 2024

From generic knick-knacks to meaningful, sustainable gifts. How US companies are rethinking their gifting strategies to align with modern values.

Why Silicon Valley is Switching to Sustainable Swag

Tech giants are leading the charge in eco-friendly merchandise. Discover why sustainable swag is the new standard for tech conferences and employee onboarding.

Maximizing Brand Visibility at Trade Shows: The Power of the Reusable Bag

In a sea of booths and flyers, a high-quality reusable bag is a walking billboard. Learn how to design trade show swag that attendees actually keep.

Understanding Plastic Bans in the US: Why Your Business Needs to Switch to Reusable Bags Now

State-by-state regulations on single-use plastics are tightening. Here’s what businesses need to know to stay compliant and ahead of the curve.

The Strategic Hue: Leveraging Color Psychology in B2B Branding and Corporate Merchandising

Discover how color psychology is a critical, non-verbal tool in B2B branding, influencing corporate purchasing decisions for premium merchandise like reusable bags. This article explores the psychological associations of core corporate colors, the strategic use of sustainable hues, and how manufacturers can leverage color consistency and contrast to build trust, convey professionalism, and elevate perceived product quality for the US market.

Beyond the Booth: Mastering Outdoor Festival Branding with Sustainable Merchandise

Outdoor festivals offer a high-impact, immersive environment for B2B branding, but success requires a strategic shift from fleeting giveaways to high-utility, sustainable merchandise. This article explores how corporate brands can leverage the festival ecosystem to build lasting brand equity, drive meaningful engagement, and demonstrate a commitment to environmental responsibility through premium, reusable products. By focusing on durability, design, and sustainable materials like rPET, brands can transform a one-time event investment into a multi-year, mobile advertising asset that aligns with the modern consumer’s values.

The Strategic Rise of Gift With Purchase (GWP) in Beauty Retail: Driving Sales with Premium Packaging

The Gift With Purchase (GWP) model has evolved from a simple bonus to a sophisticated marketing strategy in beauty retail. Discover how premium, sustainable packaging, like high-quality cosmetic pouches, is now the key driver for consumer action and brand loyalty.

University Branding: Building School Spirit and Alumni Loyalty with Premium Merchandise

Discover how premium, sustainable university merchandise can significantly enhance school spirit during student orientation and foster lifelong loyalty among alumni.

The Art of the 'Unboxing': Elevating E-commerce with Reusable Packaging Bags

Discover how e-commerce brands can transform the customer experience and meet sustainability goals by replacing traditional cardboard and plastic with premium, reusable packaging bags.

Corporate Wellness Programs: Swag that Promotes Health and Employee Engagement

Elevate your corporate wellness program with premium, health-focused swag. Discover how high-quality gym bags and insulated cooler bags can drive engagement and support healthy habits among your employees.

The Strategic Power of Premium Real Estate Marketing Gifts: Building Lasting Client Loyalty

In the hyper-competitive landscape of US real estate, a successful transaction is only the beginning. The true measure of a top-tier real estate professional lies in their ability to cultivate a robust network of referrals and repeat business. This longevity is not built on closing deals alone, but on the sustained, positive impression left on every client.

Trade Show Booth Design: Integrating Swag into Your Visuals for Maximum Impact

Elevate your trade show presence by integrating high-quality branded bags into your booth's visual design. Learn creative display techniques like 'Bag Walls' and illuminated podiums to transform swag from clutter into a powerful, premium branding statement.

Beyond the Checkout: The Complete Sustainability Lifecycle of a Reusable Bag

A deep dive into the complete sustainability lifecycle of a reusable bag, from material sourcing and production to end-of-life management. This B2B-focused article provides decision-makers with the data on material trade-offs, the critical 'break-even' point for reusability, and the business case for investing in durable, circular-economy-focused promotional bags to meet regulatory compliance and consumer demand.

Canvas vs. Cotton: Detailed Material Analysis for Corporate Totes

A Textile Engineer's in-depth analysis of cotton and canvas for corporate totes, focusing on fiber structure, durability testing, and environmental impact.

Screen Printing vs. Digital Transfer: A Production Manager's Guide to Bulk Logo Decoration

A Production Manager's objective analysis of screen printing and digital transfer. Compares durability, color vibrancy, cost-effectiveness for bulk orders, and halftone limitations.

The GSM Standard: Why Fabric Weight is the Ultimate Metric for Bag Durability and Load-Bearing Capacity

A Quality Control Specialist's deep dive into Grams per Square Meter (GSM), explaining how this critical metric dictates fabric density, load-bearing capacity, and overall bag durability.

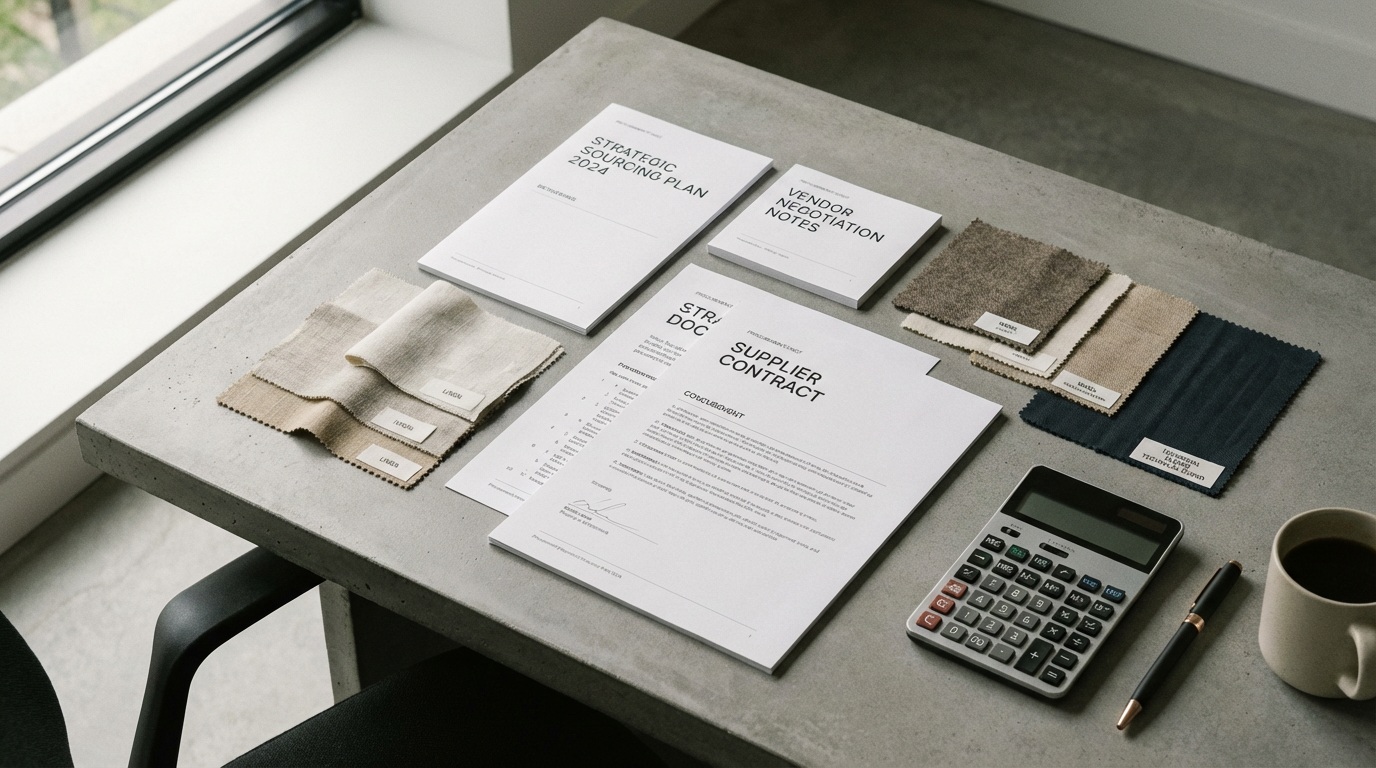

The Strategic Procurement Officer's Guide to Negotiating Minimum Order Quantities (MOQ)

A strategic guide for Procurement Officers on negotiating Minimum Order Quantities (MOQ), covering strategies for startups vs. enterprises and hidden costs.

The Supply Chain Manager's Guide to Quality Control: Mastering AQL and Pre-Shipment Inspection

A deep dive into the quality control process for bags, detailing the step-by-step application of AQL standards, common stitching and printing defects, and the critical importance of pre-shipment inspection for supply chain integrity.

Mastering the Supply Chain: A Logistics Coordinator's Guide to Lead Time Management from Factory to Freight

A comprehensive guide for Logistics Coordinators on deconstructing and managing the complex lead time from initial design and material sourcing through manufacturing and final delivery.

The 2025 Outlook: Key Corporate Gifting Trends Shaping the US Market

An in-depth analysis of the US corporate gifting landscape for 2025, focusing on remote work kits, eco-conscious unboxing, and the 'Made in USA' sourcing debate.

Compliance Roadmap: Navigating Sustainable Packaging Regulations in California (SB 270) and New York

A deep dive for Compliance Officers into California's SB 270 and New York's Bag Waste Reduction Law, detailing compliance requirements and the strategic shift from thin-film to durable reusable packaging.

The Event Planner's Guide to Tech Conference Swag: Best Practices for Silicon Valley Events

A professional guide for event planners on selecting high-quality, functional swag for tech conferences in Silicon Valley, focusing on laptop-friendly items and moving beyond cheap plastic.

The Strategic Advantage: High-End Totes in Luxury Real Estate Marketing

For luxury real estate in competitive markets like Miami and NYC, high-end branded totes elevate the open house experience, reinforce brand quality, and serve as memorable closing gifts.

Screen Printing vs. Digital Transfer: A Technical Analysis for High-Volume Bag Production

This technical analysis compares screen printing and digital transfer methods for high-volume bag production, focusing on critical engineering metrics like ink viscosity, curing temperatures, substrate adhesion, and color fastness testing standards. The choice between the two methods is determined by a complex calculation involving volume, color count, and the desired durability profile.

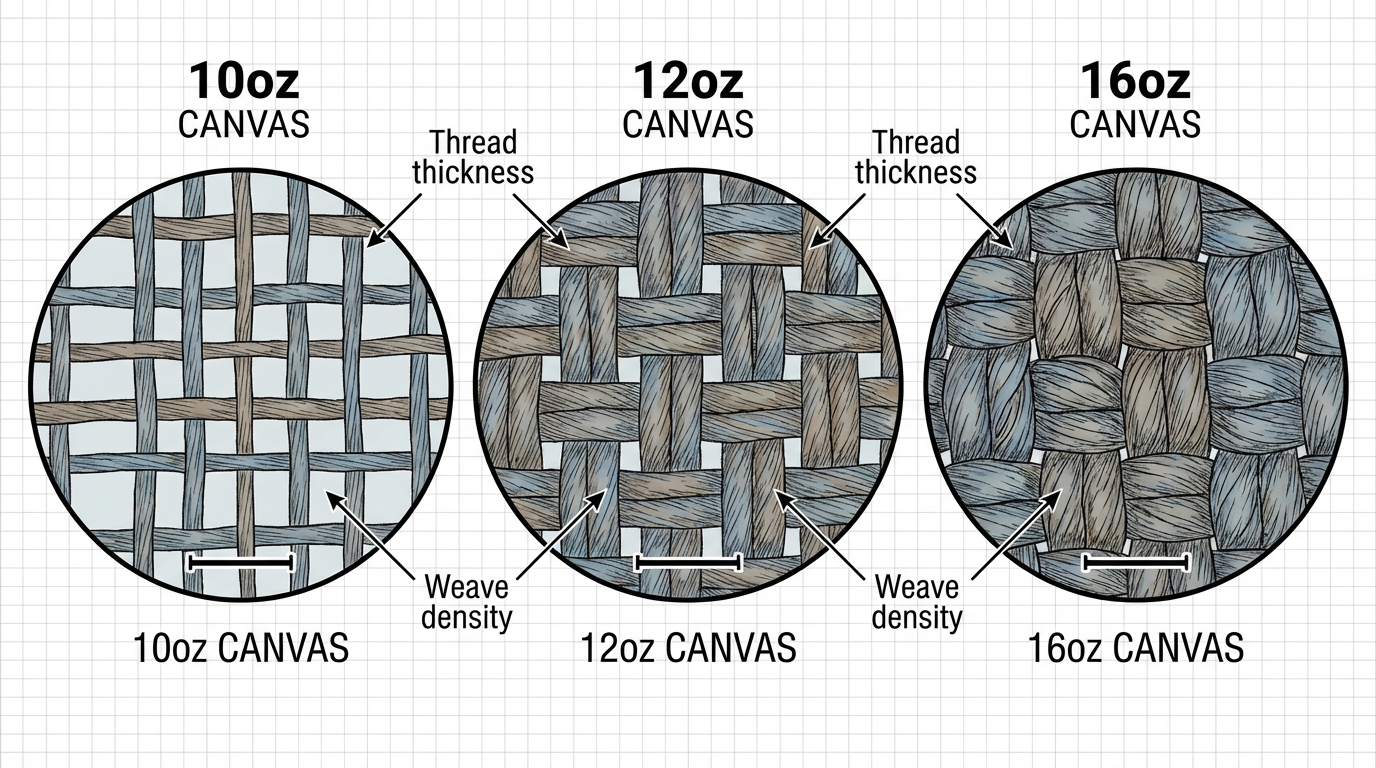

Deconstructing Canvas Weight: The Engineering Behind 10oz, 12oz, and 16oz Fabrics

Canvas weight, measured in ounces per square yard (oz/yd²), is the key engineering metric that determines a fabric's tensile strength, load-bearing capacity, and abrasion resistance. A heavier canvas, such as 16oz, signifies a denser weave and greater fiber volume, leading to superior durability for heavy-duty applications compared to lighter 10oz and 12oz fabrics.

The Chemistry of Color: A Deep Dive into Sustainable Dyeing Processes for Corporate Textiles

As a Chemical Process Engineer, I detail the critical shift to sustainable dyeing for corporate textiles, focusing on the chemical necessity of AZO-free dyes, the engineering strategies for reducing water consumption, the multi-stage approach to effluent treatment, and the rigorous process controls required to ensure color consistency across large production batches.

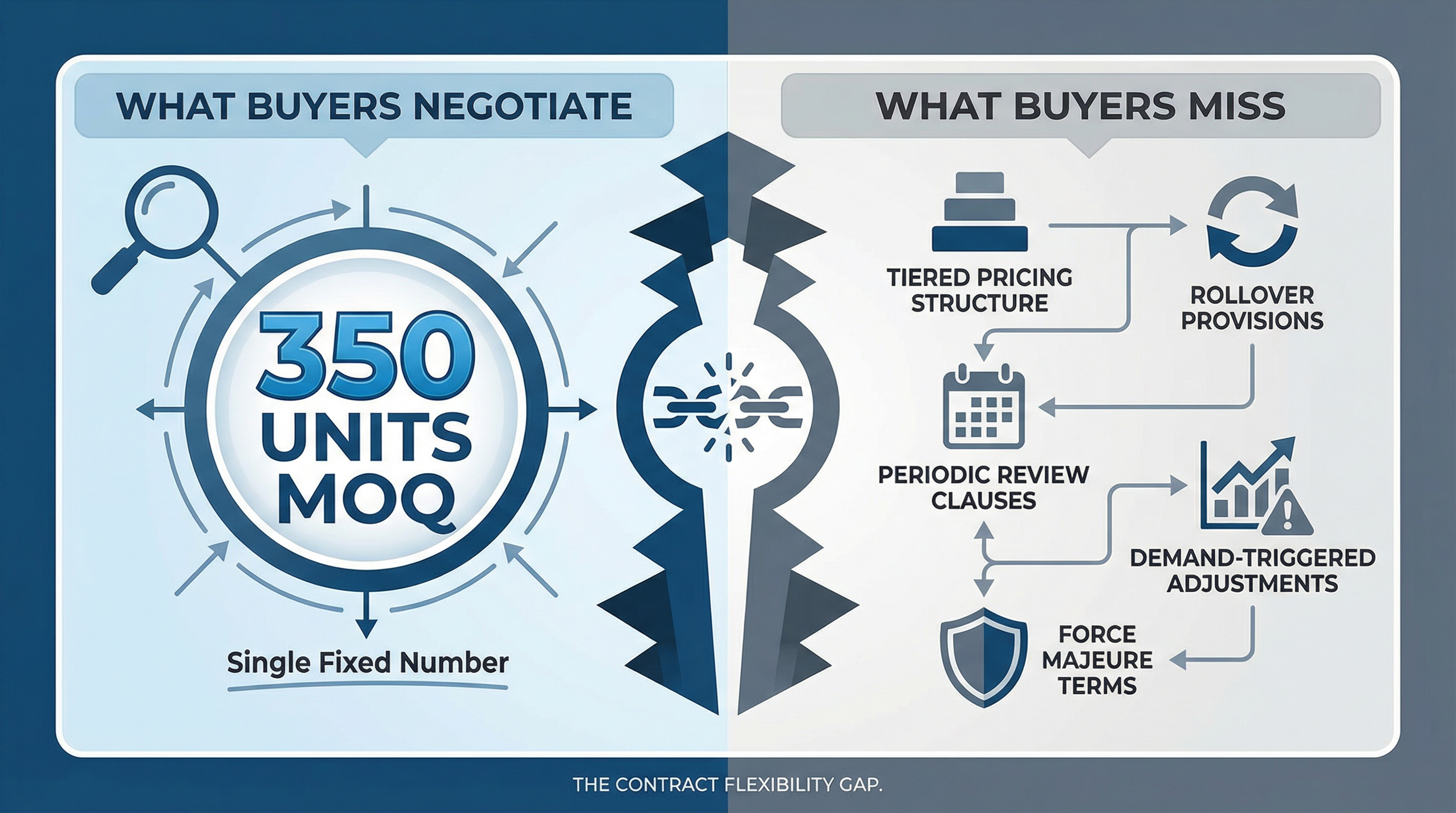

Beyond the Price Tag: Strategic MOQ Negotiation for Custom Bag Orders

For supply chain managers, the Minimum Order Quantity (MOQ) is a strategic lever, not a fixed barrier, requiring negotiation based on a deep understanding of economies of scale and inventory holding costs. This article details how to leverage tiered pricing, long-term commitments, and data-driven TCO models to secure optimal custom bag orders.

Zero-Defect Protocol: Implementing Rigorous QC Standards in Bag Manufacturing

As a QC Inspection Lead, I detail the Zero-Defect Protocol, a rigorous system for bag manufacturing that utilizes AQL standards, destructive stitch stress testing, and cyclic handle reinforcement checks to ensure product durability and aesthetic precision.

Mitigating Supply Chain Risk: A Logistics Playbook for Time-Critical Corporate Events

As a Logistics Director, mitigating supply chain risk for time-critical corporate gifting requires a strategic playbook focused on buffer stock, rigorous freight forwarder selection, proactive customs clearance, and resilient last-mile delivery. This approach transforms potential logistical failures into controlled, predictable processes that protect brand reputation and ensure timely delivery.

Navigating the West Coast Gateway: How Port of LA Congestion Impacts Corporate Swag Timelines

The Port of Los Angeles and Long Beach is the critical gateway for US imports, but persistent congestion, chassis shortages, and rising drayage costs are creating significant delays and financial risks for corporate swag timelines. Import Specialists recommend a multi-pronged strategy, including extended planning horizons and leveraging alternative ports, to mitigate the cascading effects of West Coast port volatility on the intermodal rail network and final delivery schedules.

Street Style to Showroom: Promotional Bag Trends from New York Fashion Week

New York Fashion Week street style reveals that promotional bags are now coveted accessories, with a clear trend toward sustainable luxury and sophisticated silhouettes. Fashion merchandisers must prioritize high-quality, ethically sourced materials and agile sourcing to capitalize on the rapid pace of urban trends.

The Silicon Hills Effect: Corporate Gifting Culture in the Austin Tech Corridor

The Austin tech scene, known as Silicon Hills, demands corporate swag that reflects its unique blend of high-octane innovation and laid-back, outdoor-centric culture. Event planners must prioritize utility, premium design, and local authenticity, moving away from disposable items to durable gear that enhances the recipient's dynamic lifestyle.

Heartland Industry: Trade Show Bag Trends from Chicago's McCormick Place

As a Trade Show Director navigating the Chicago convention circuit, the key trend is a shift toward heavy-duty, winter-ready promotional bags that prioritize durability and utility over fleeting aesthetics. The harsh Midwest climate and the heavy nature of industrial collateral demand structured, water-resistant carriers, like high-denier non-woven bags, to ensure brand longevity and attendee satisfaction.

From Bottle to Bag: The Engineering Behind rPET Fabric Manufacturing

As a material engineer, I provide a detailed, authoritative breakdown of the Recycled Polyethylene Terephthalate (rPET) fabric manufacturing process, from post-consumer plastic bottle collection to final textile production. This article is a critical guide for B2B buyers in the US market, focusing on the engineering precision, quality control checkpoints (like IV testing and filtration), and regulatory compliance necessary to source high-quality, durable, and sustainable rPET materials that meet rigorous commercial demands.

Screen Printing vs. Heat Transfer: A Technical Analysis of Ink Durability on Canvas

For B2B buyers, the choice between screen printing and heat transfer on canvas is critical. The most critical factor determining long-term durability is the mechanical bond and elasticity between the ink layer and the canvas fibers. Screen printing achieves a superior mechanical bond by penetrating the weave, while heat transfer relies on a surface-level adhesive, making it more susceptible to wear.

Decoding GSM and Oz: A Technical Guide to Canvas Weight and Structural Integrity

For B2B buyers, understanding the technical specifications of canvas weight—measured in Grams per Square Meter (GSM) and Ounces per Square Yard (Oz/yd²)—is crucial for predicting a product's structural integrity and longevity. This guide, written from the perspective of a Textile Quality Engineer, decodes the science behind these metrics, comparing the performance differences between 12 oz and 16 oz canvas to ensure optimal material sourcing for heavy-duty commercial applications in the US market.

Mitigating Risk: Strategies for Navigating Global Supply Chain Disruptions in 2025

The global supply chain environment in 2025 demands a shift from reactive measures to proactive, systemic strategies. Written from the perspective of a Global Supply Chain Manager, this article details how US-based B2B enterprises can embed resilience into their core operations through multi-tiered sourcing, real-time data analytics, and strategic buffer stock management to navigate persistent uncertainty and freight volatility.

Beyond the Price Tag: Optimizing MOQ Negotiations for Custom Bag Orders

As a Procurement Director, I detail how to move beyond the sticker price and treat Minimum Order Quantity (MOQ) as a strategic negotiation point for custom bag orders. Learn to leverage non-price concessions like favorable payment terms, lead time flexibility, and rolling forecasts to align your inventory needs with supplier efficiencies, ensuring a resilient and cost-effective B2B supply chain.

The Zero-Defect Standard: A Comprehensive QC Checklist for Large-Scale Corporate Orders

As a QC Inspection Lead, my focus is always on mitigating risk for our B2B clients. When a company invests in thousands of custom-branded items for a major corporate event, the margin for error is effectively zero. This article details a rigorous, four-phase Quality Control (QC) checklist—covering pre-production material verification, in-line monitoring (DUPRO), Final Random Inspection (FRI) using AQL standards, and final packaging checks—designed to establish a true zero-defect standard for large-scale corporate merchandise orders in the US market. It provides actionable insights for B2B buyers on how to enforce dimensional consistency, verify color accuracy, and ensure compliance with critical US safety and ethical sourcing regulations.

Navigating California Prop 65: Compliance for Corporate Gifting in the West Coast

As a Regulatory Compliance Officer, I detail the critical steps B2B buyers and suppliers must take to ensure their corporate gifting and promotional products, especially items like reusable bags, comply with California's Proposition 65, focusing on warning requirements, safe harbor levels, and the financial risks of non-compliance.

Lessons from the Runway: Sustainable Swag Trends Influenced by NY Fashion Week 2025

As a NY Trend Analyst, I break down the definitive shift in corporate gifting and merchandise, heavily influenced by the sustainability commitments seen at NY Fashion Week 2025. The new mandate for B2B buyers is high-quality, ethically sourced, and genuinely useful items, moving past disposable swag and embracing circularity, transparency, and the "quiet luxury" aesthetic. This article explores the material innovations and strategic shifts necessary for brands to align their merchandise with the values of the modern, conscious US consumer.

Stand Out in Silicon Hills: Tech Conference Swag Trends from Austin's SXSW

Austin's SXSW demands a strategic approach to promotional products that moves beyond cheap trinkets. This article, written from the perspective of an Event Marketing Specialist, explores the current trends in tech conference swag, focusing on utility, sustainability, and brand storytelling to ensure B2B buyers make a lasting impression in the competitive Silicon Hills market. Key strategies include prioritizing high-quality, reusable items like Canvas Tote Bags, ensuring ethical sourcing, and integrating tech-enabled experiences via NFC chips or QR codes for measurable engagement.

Practicality Reigns: Manufacturing Expo Giveaway Trends in the Industrial Midwest

The Industrial Midwest's manufacturing expos demand promotional giveaways that are not just memorable, but genuinely useful and durable. As an Industrial Marketing Manager, I've seen firsthand that attendees value items that can withstand the rigors of a factory floor or a job site, making high-quality, customized promotional bags the superior choice for B2B corporate gifting in this critical sector.

Canvas vs. Jute: A Material Engineer's Technical Comparison for Corporate Totes

A deep-dive technical analysis comparing tensile strength, abrasion resistance, and printability of 12oz Canvas vs. High-Density Jute for corporate applications.

Screen Printing vs. Heat Transfer: A Production Manager's Workflow Breakdown

Dissecting the production steps, equipment requirements, and bottleneck risks of Screen Printing vs. Digital Heat Transfer for bulk orders.

Supply Chain Risk Management: A Procurement Director's Memo on 2025 Gifting Strategies

Navigating raw material shortages, freight volatility, and vendor consolidation risks in the 2025 corporate gifting landscape.

US Corporate Gifting: A Guide to Compliance, Culture, and Cycles for 2025

Understanding the nuances of US corporate gifting laws (Gift Ban Act), regional preferences, and the critical Q4 procurement cycle.

Silicon Valley Swag: Why Tech Giants Are Ditching Cheap Plastics for Premium Utility

Analyzing the shift in tech sector merchandise from throwaway gadgets to high-quality, sustainable utility gear in San Francisco and Austin.

What Is the Minimum Order Quantity for Custom Reusable Bags?

Comprehensive guide to MOQ requirements for custom reusable bags in the US market, covering material-specific minimums, supplier types, and strategic procurement approaches for enterprises.

Why MOQ Decisions for Custom Reusable Bags Are Often Misjudged

Procurement teams focus on the MOQ number itself, missing the structural cost drivers and ordering behaviors that create unnecessary expense. A factory project manager explains where the decision-making framework breaks down.

When MOQ Commitments Become Liabilities: The Contract Flexibility Blind Spot

Buyers negotiate MOQ numbers down but miss the contractual flexibility needed when demand forecasts inevitably prove wrong. Understanding how to structure adjustment mechanisms, rollover provisions, and tiered pricing prevents rigid commitments from becoming operational liabilities.

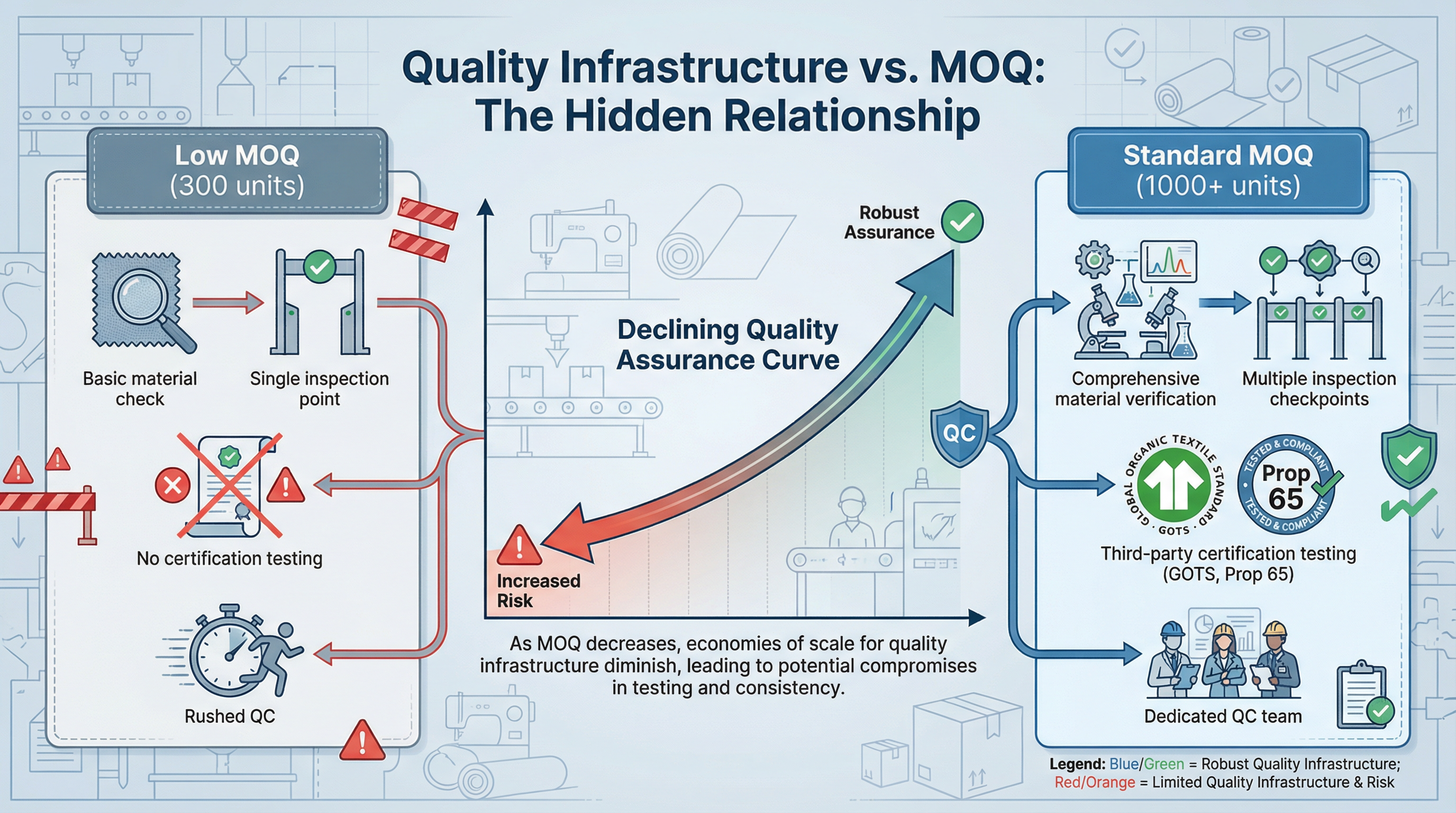

The Quality-Compliance Blind Spot in MOQ Negotiations for Custom Reusable Bags

Why negotiating MOQ in isolation compromises quality infrastructure, testing protocols, and certification requirements—and how to structure procurement discussions that account for the full scope of compliance needs.

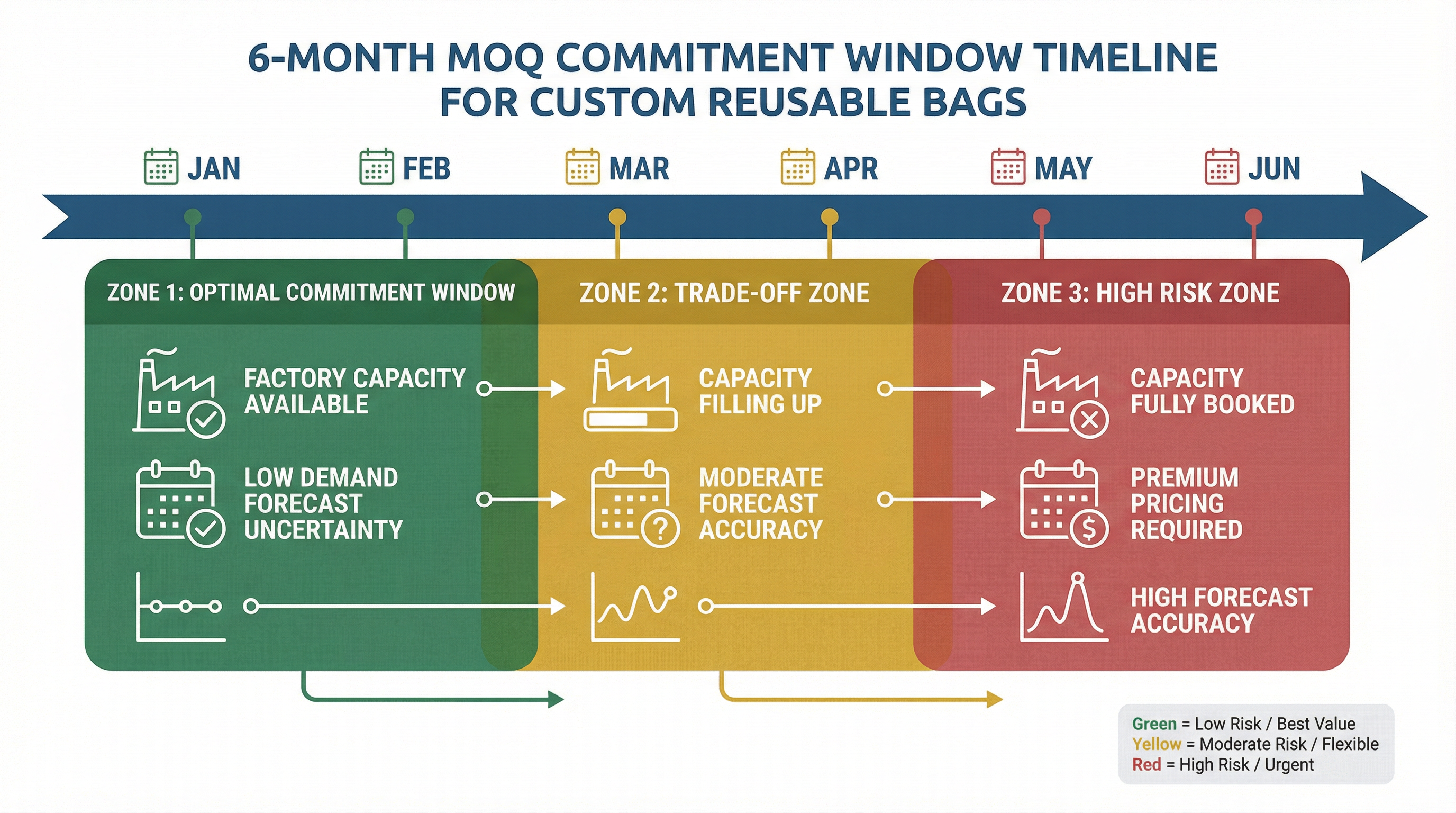

The MOQ Timing Blind Spot: When Commitment Windows Matter More Than Quantity

Procurement teams negotiate MOQ numbers but miss the critical timing decision. For custom reusable bags with 90-120 day lead times, the real question isn't what MOQ you can negotiate—it's when you commit to that MOQ relative to your demand cycle, production capacity windows, and forecast accuracy.

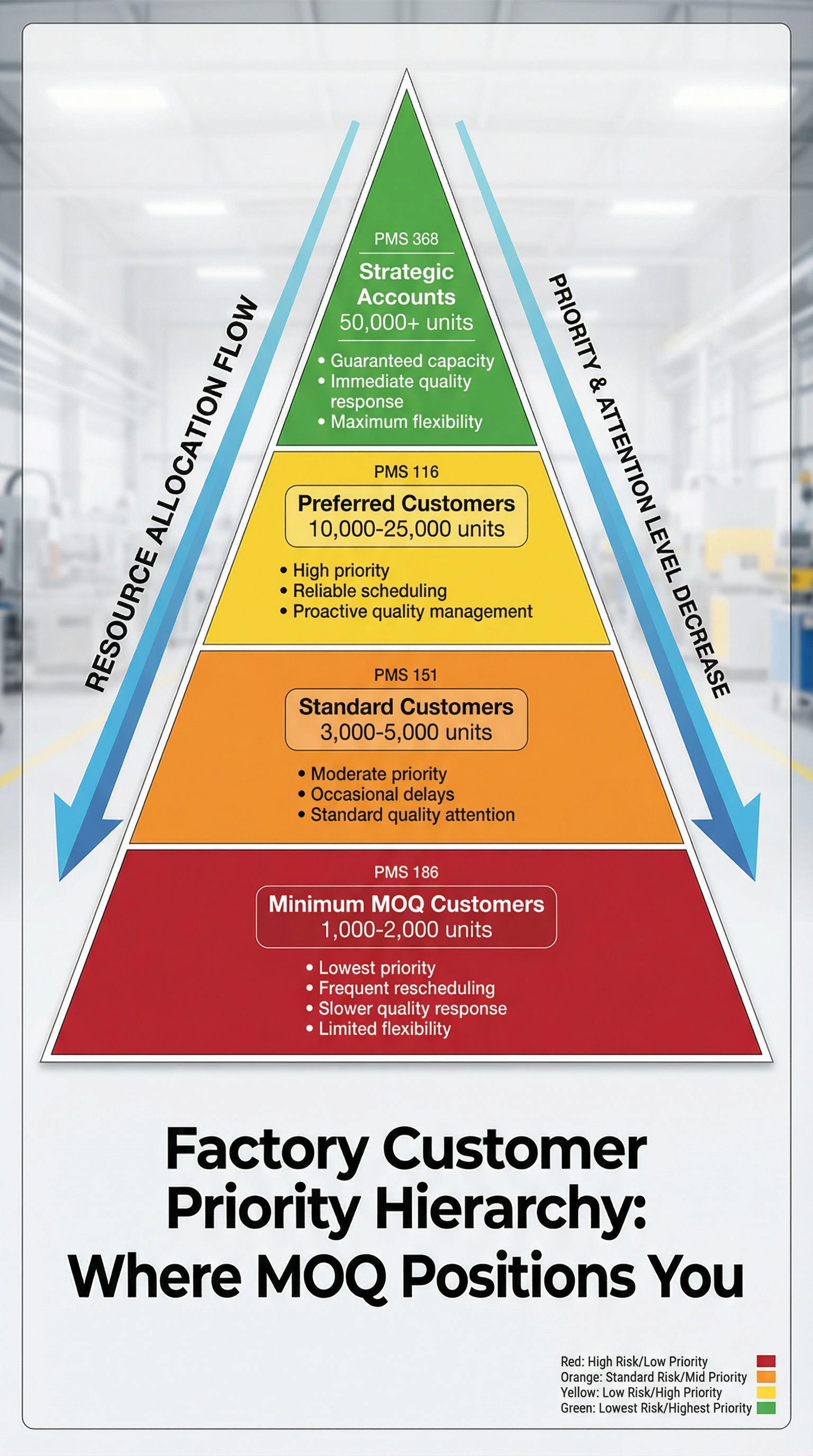

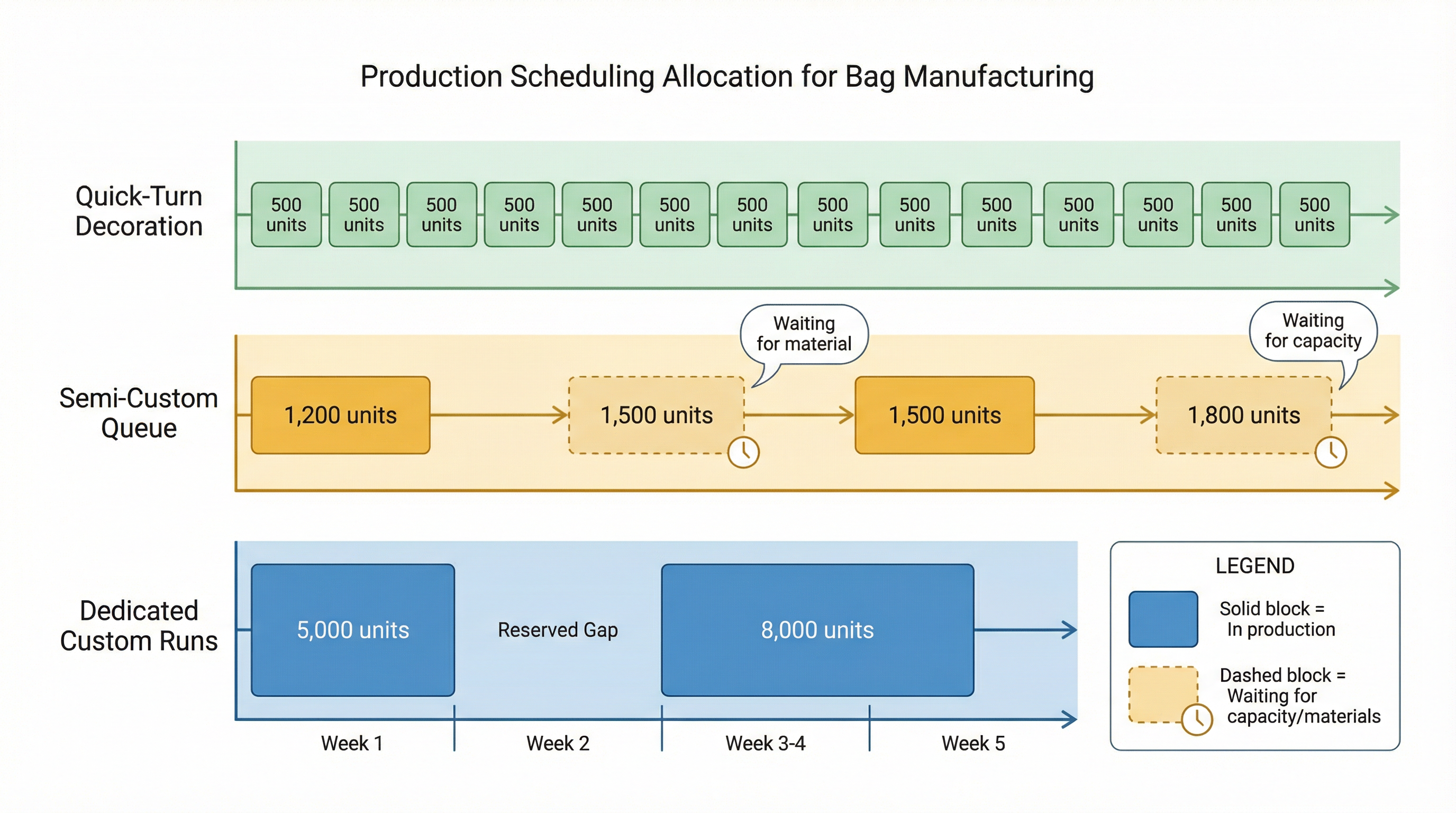

The MOQ Priority Queue Blind Spot in Custom Reusable Bag Procurement

Meeting the minimum order quantity doesn't secure equal treatment—it positions you in a competitive hierarchy that determines service levels, quality attention, and delivery reliability.

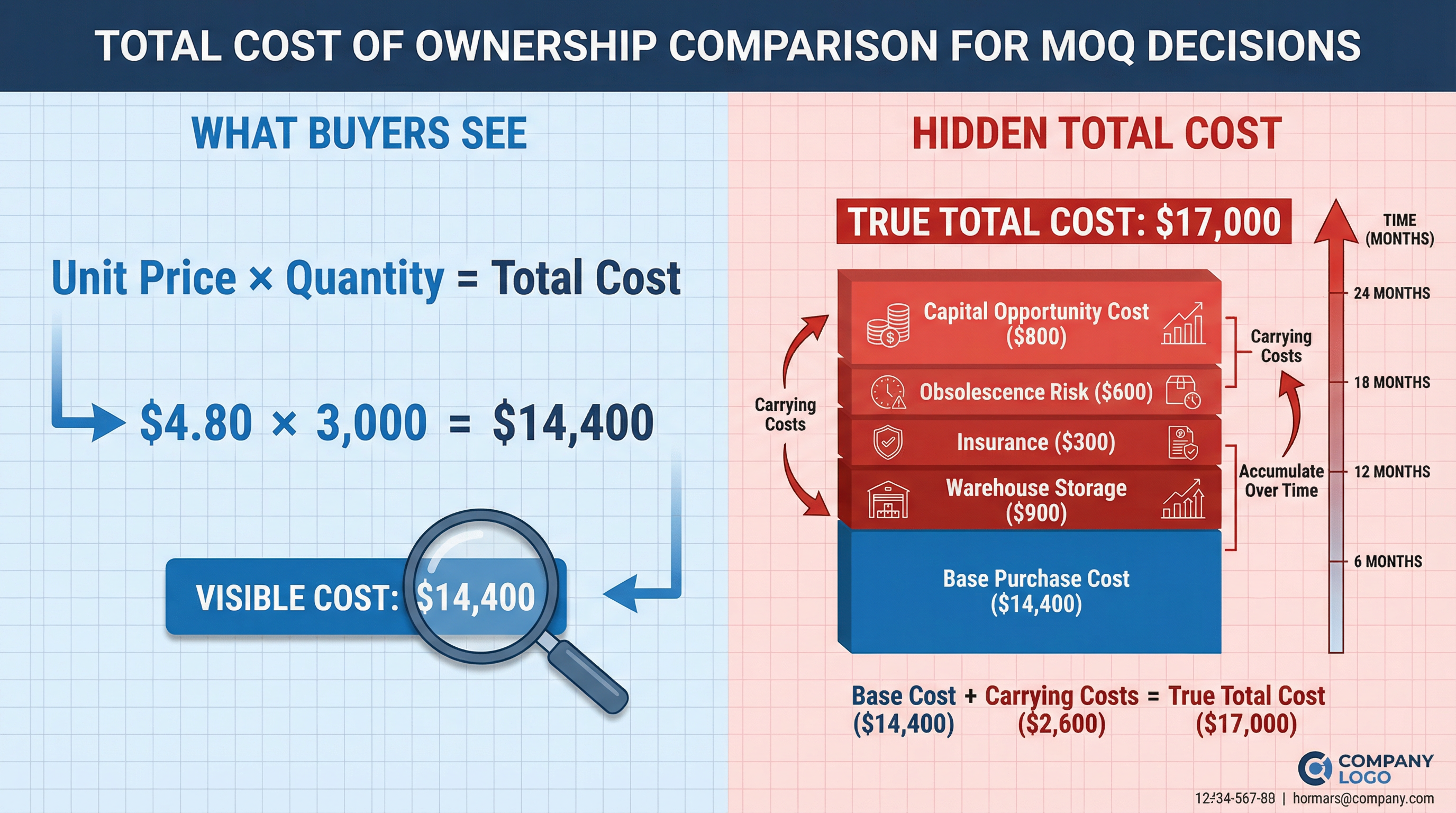

The Inventory Carrying Cost Blind Spot in MOQ Decisions for Custom Reusable Bags

Procurement teams focus on per-unit price when evaluating MOQ, but carrying costs that accumulate over months of storage often exceed the initial savings. This blind spot persists because decision-makers are measured on acquisition cost, not total cost of ownership.

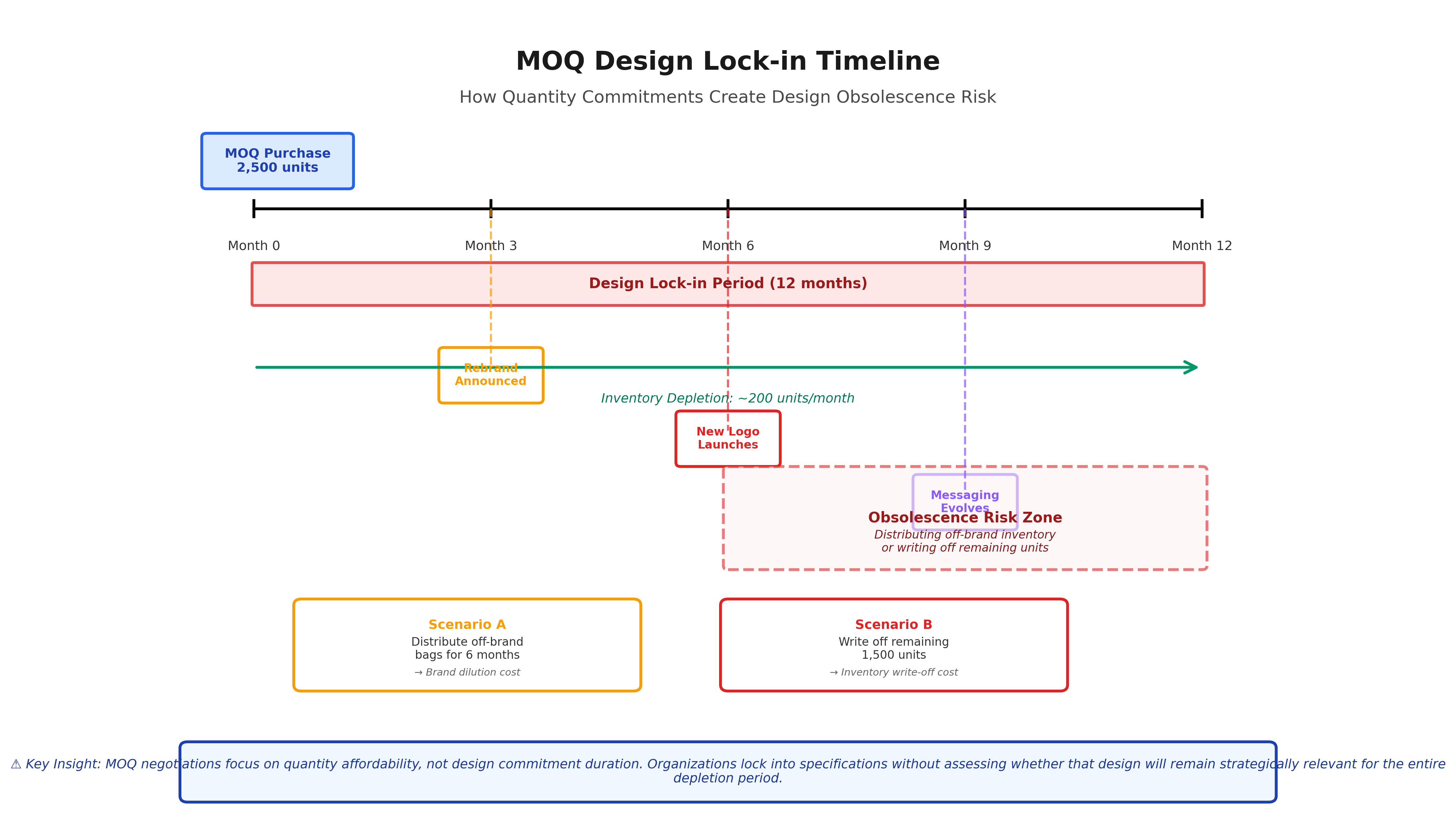

The Design Iteration Blind Spot in MOQ Commitments for Custom Reusable Bags

Procurement teams negotiate MOQ focusing on quantity and price, but miss the design lock-in that commitment creates. Organizations find themselves distributing bags with outdated branding, obsolete messaging, or off-strategy designs because the MOQ decision didn't account for how long that specific design would remain strategically relevant.

The Multi-SKU Complexity Blind Spot in MOQ Negotiations for Custom Reusable Bags

Procurement teams negotiate MOQ as a single aggregate number without recognizing that splitting across multiple SKUs multiplies setup costs, fragments production efficiency, and creates quality control challenges. A 3,000-unit order split across six designs has fundamentally different economics than 3,000 units of a single design.

The Supplier Capacity Verification Blind Spot in MOQ Negotiations for Custom Reusable Bags

Buyers negotiate MOQ commitments without verifying whether the supplier has the actual production capacity—considering equipment availability, workforce, current order backlog, and realistic defect rates—to fulfill that order within the required timeline. This leads to rushed production with quality compromises, delivery delays, or unauthorized subcontracting.

The Payment Terms Blind Spot in MOQ Negotiations for Custom Reusable Bags

Procurement teams negotiate MOQ based on per-unit economics and total capital outlay, but fail to negotiate payment term structures that align with organizational cash flow cycles. The timing mismatch between payment obligations and revenue realization from distributed bags creates liquidity crises that could have been avoided through better payment term negotiation.

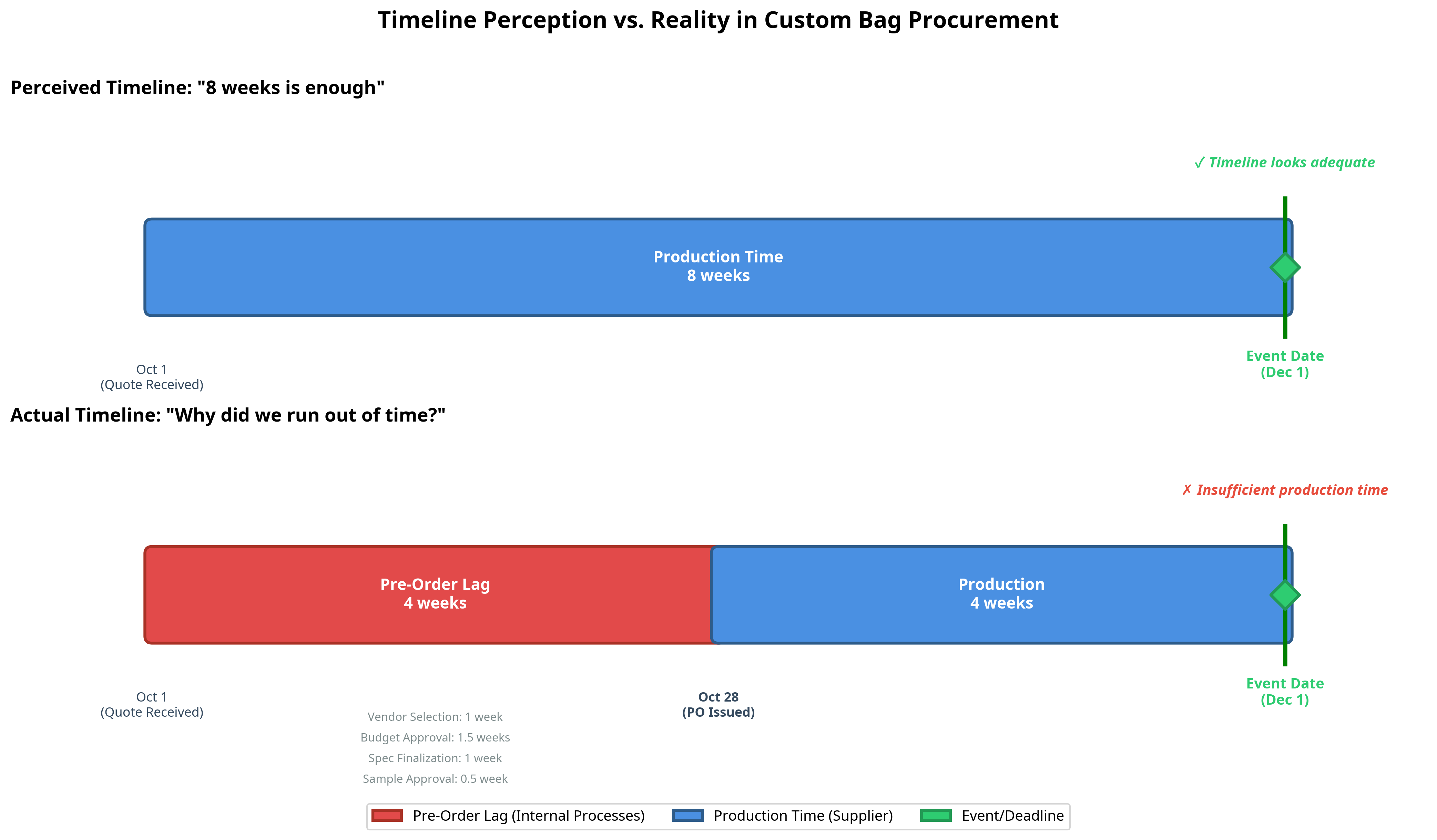

The Hidden Pre-Order Timeline in Custom Bag Production

Corporate procurement teams consistently underestimate the time between recognizing a need and placing an order. This pre-order lag consumes 30-50% of available timeline in mid-sized to large organizations, creating predictable delivery failures attributed to supplier performance when the root cause lies in internal decision-making velocity.

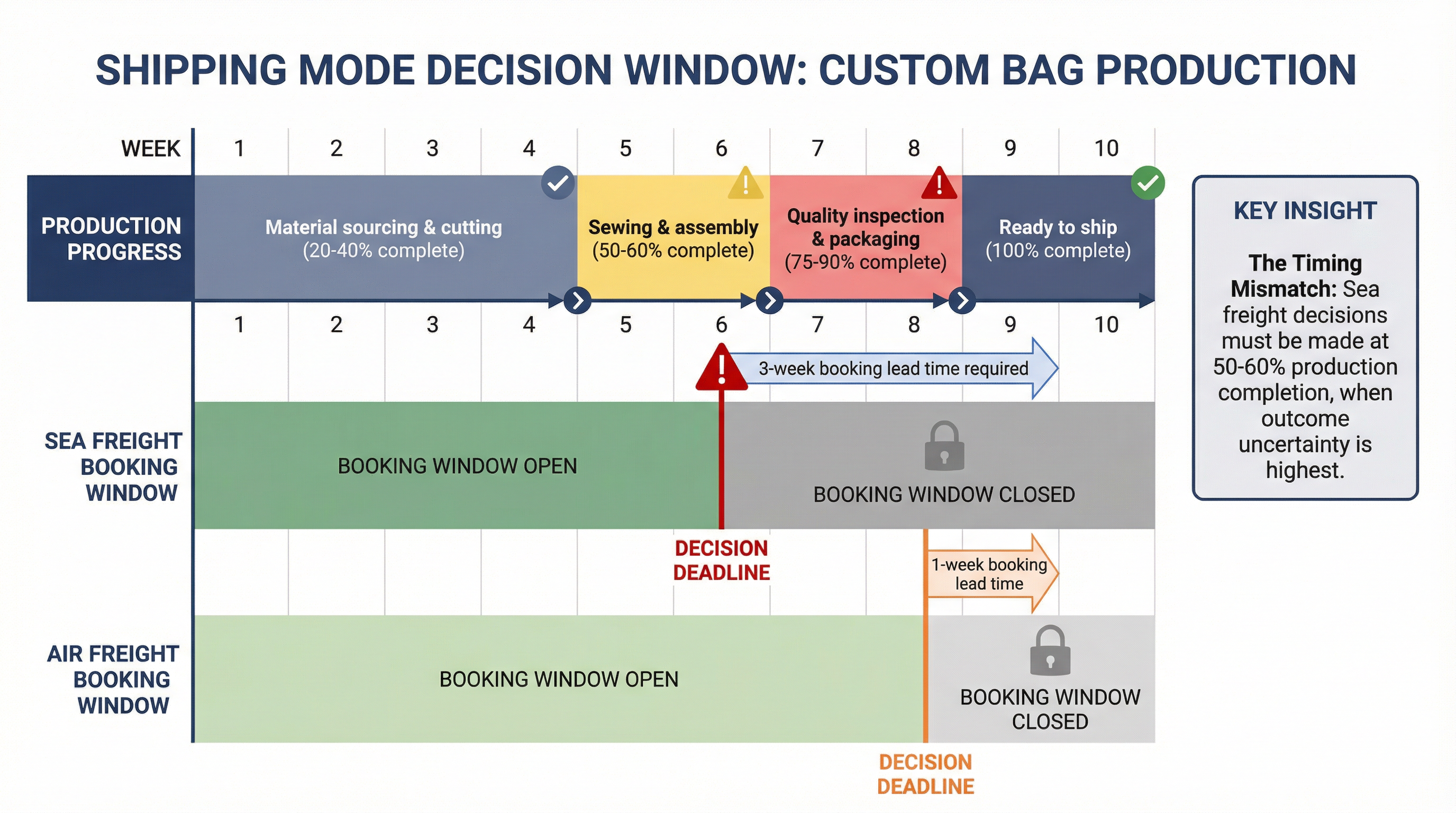

The Shipping Mode Decision Window in Custom Reusable Bag Production

Factory project managers observe a predictable failure pattern: buyers commit to sea freight based on optimistic production timelines, then scramble for air freight when delays surface, often paying five to eight times the original logistics budget.

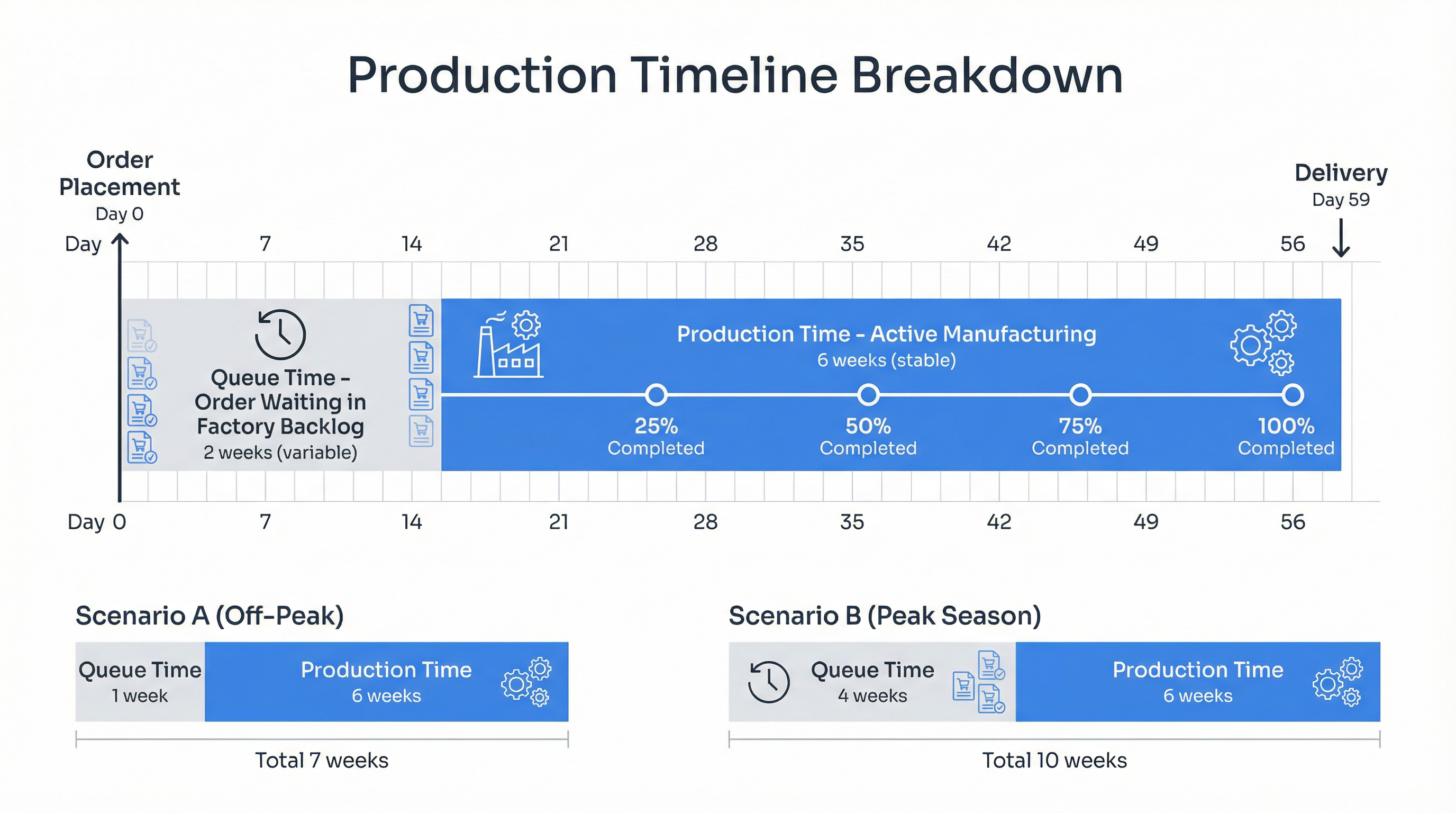

The Production Queue Blind Spot: When Your Order's Start Date Isn't What You Think

Procurement teams ordering custom reusable bags operate under a persistent assumption: that quoted lead times represent the duration from order placement to delivery. The reality is that production queue time—the weeks your order waits before manufacturing begins—remains invisible in most supplier conversations.

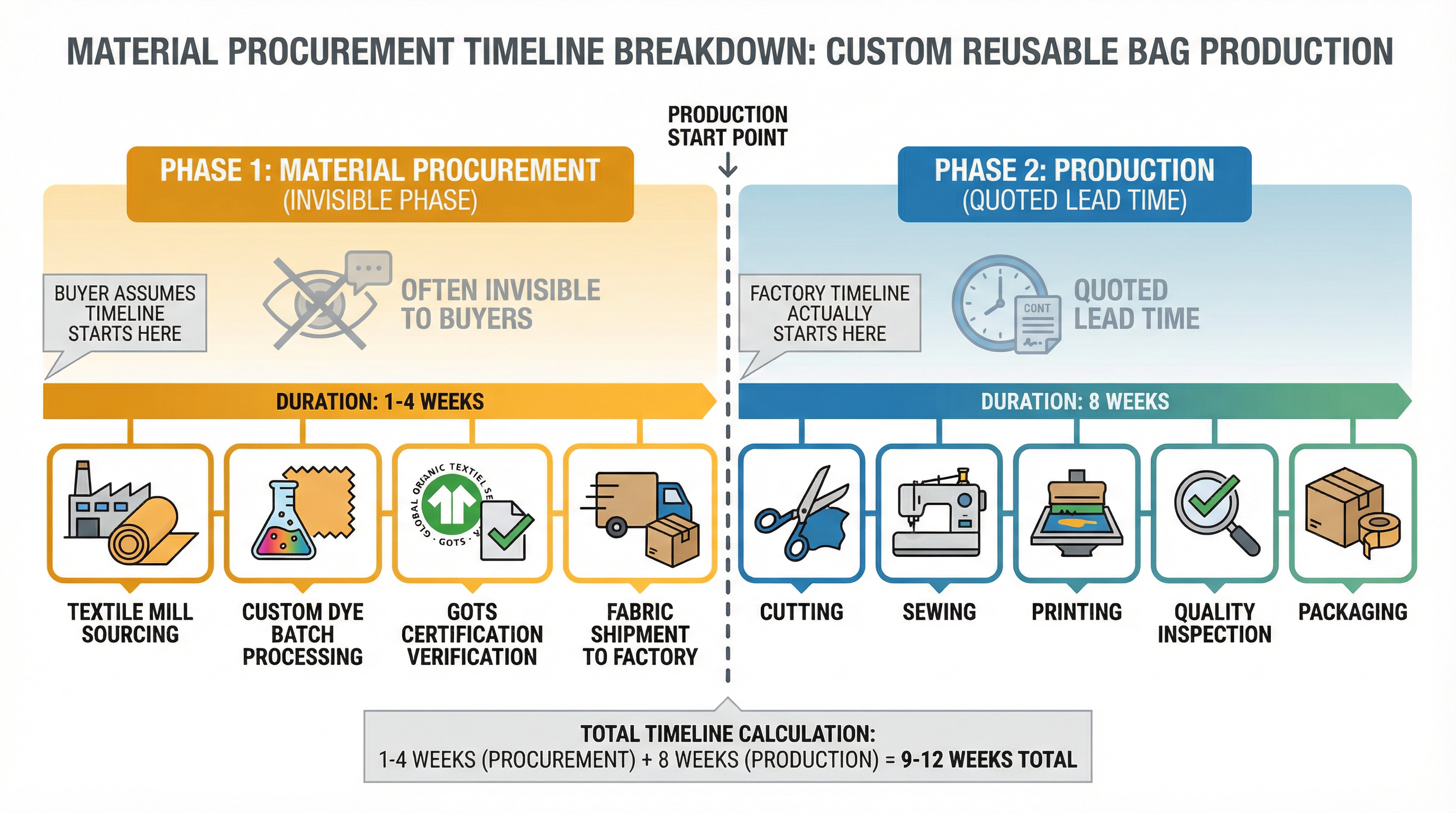

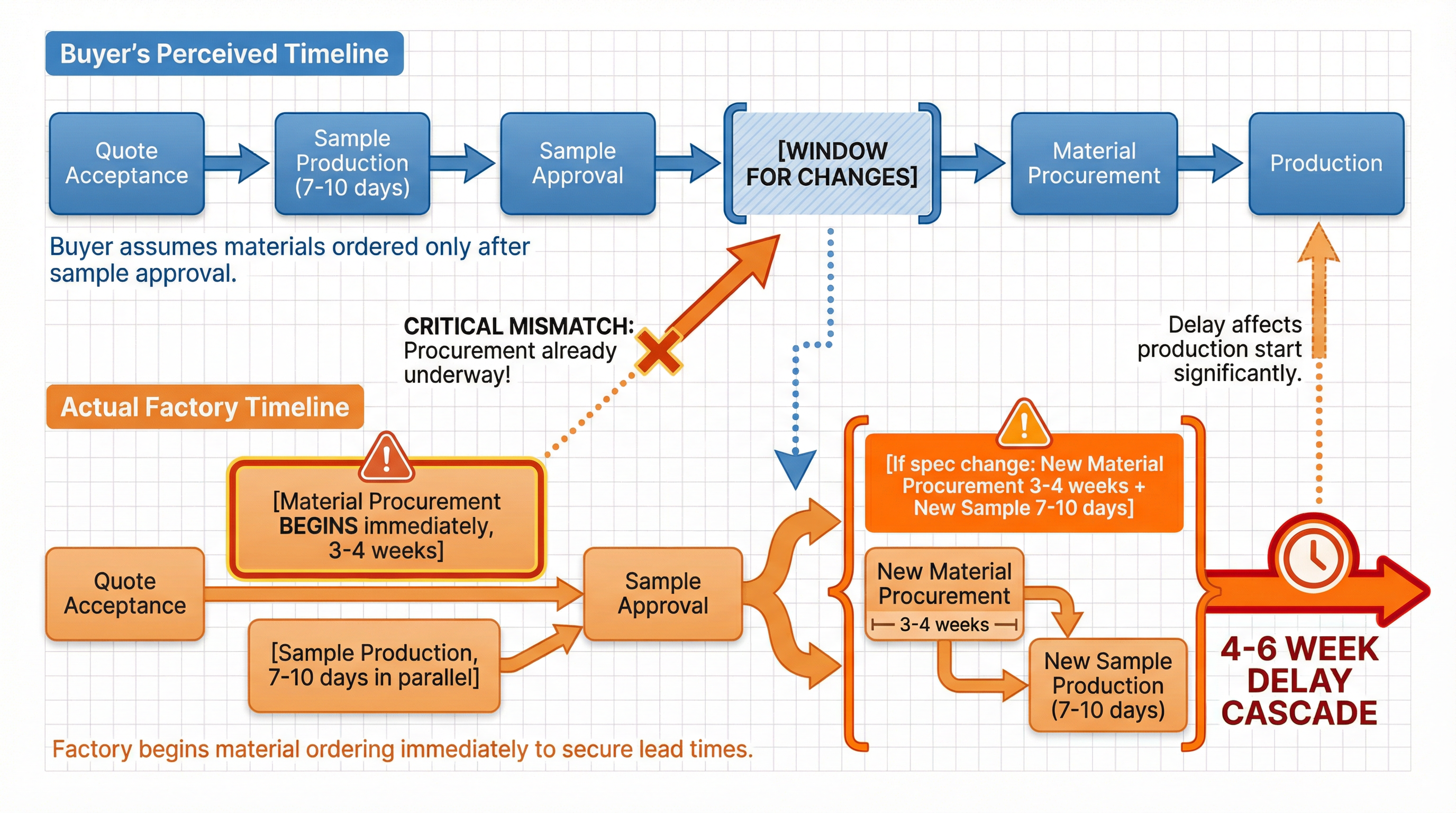

The Material Procurement Timing Gap: When Production Lead Time Doesn't Include Material Sourcing

Compliance teams reviewing custom reusable bag orders verify quoted lead times, approve sustainable materials, and sign off with confidence. Then production delays surface because no one understood that quoted timelines assume materials are already available—not that procurement time is included.

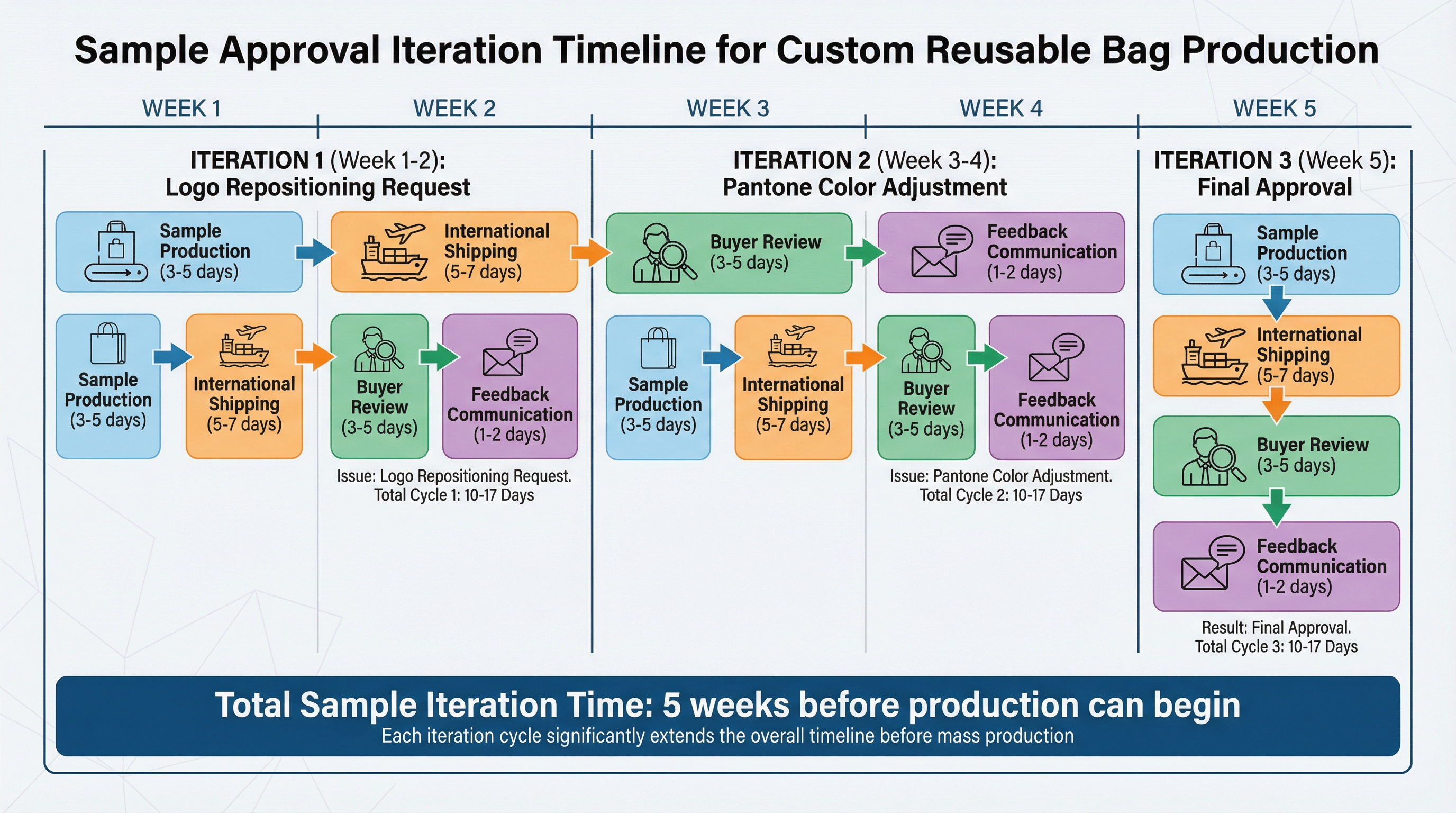

The Sample Approval Iteration Lag: When Production Timelines Assume a Final Sample That Doesn't Yet Exist

Procurement teams reviewing custom reusable bag orders verify quoted lead times and approve orders with confidence. Then production delays surface because no one understood that the timeline assumes a final approved sample—not the first sample that requires two or three revision cycles.

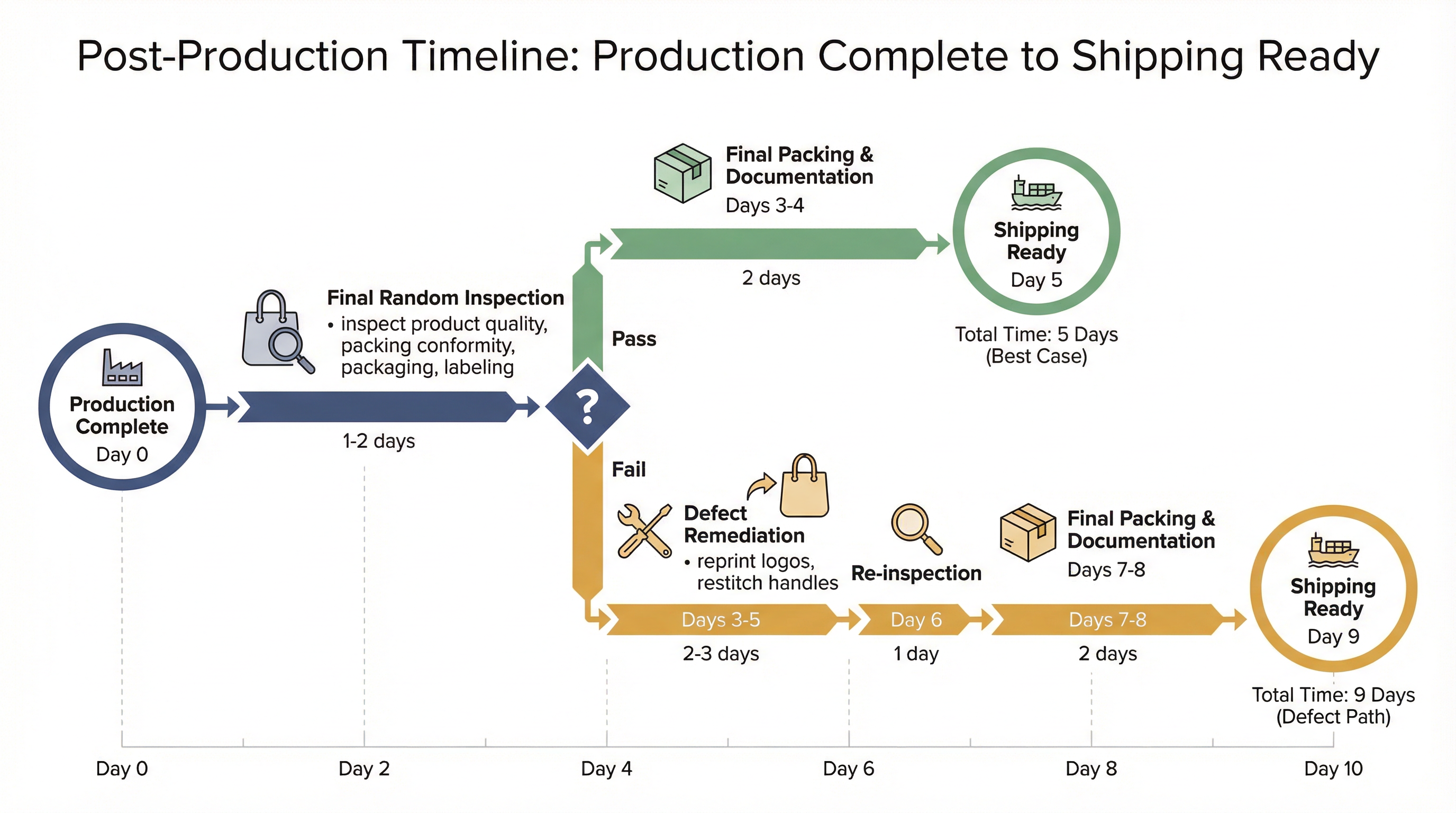

When Production Completes On Schedule But Shipping Still Starts Late: The Quality Control Timeline Compression

Corporate buyers ordering custom reusable bags assume that when the factory reports 'production complete,' the goods are ready to ship. This conflation of 'manufacturing finished' with 'ready for export' creates predictable delays as quality control, remediation, and documentation phases consume six to twelve additional days.

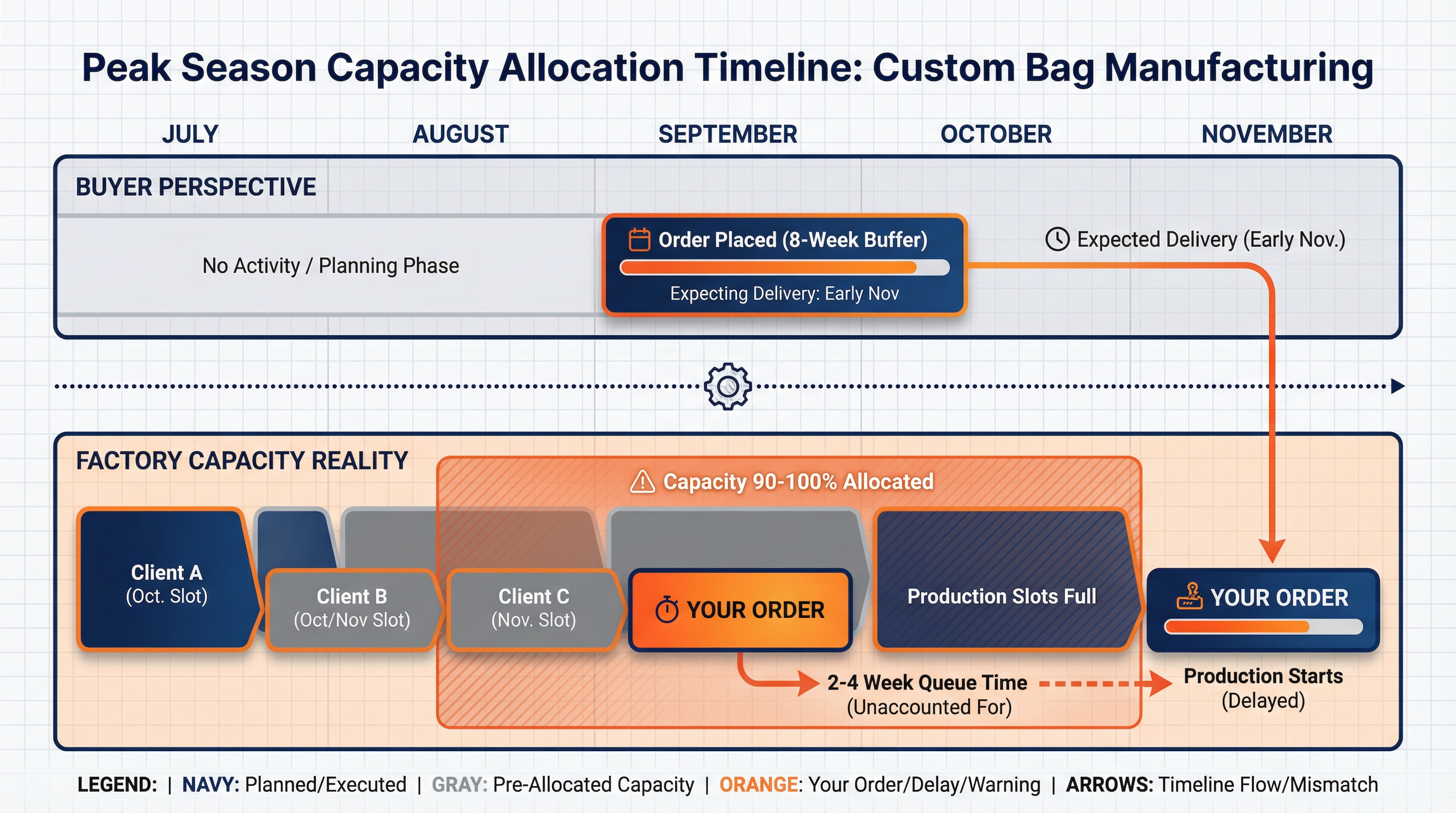

Why August Orders Arrive On Time But September Orders Don't: The Peak Season Capacity Pre-Allocation Blind Spot

Buyers ordering custom reusable bags in early September with an eight-week buffer assume their November event is well-planned. Yet these orders consistently arrive late because factory capacity operates like airline seats—production slots for October and November are already claimed by clients who ordered in July and August.

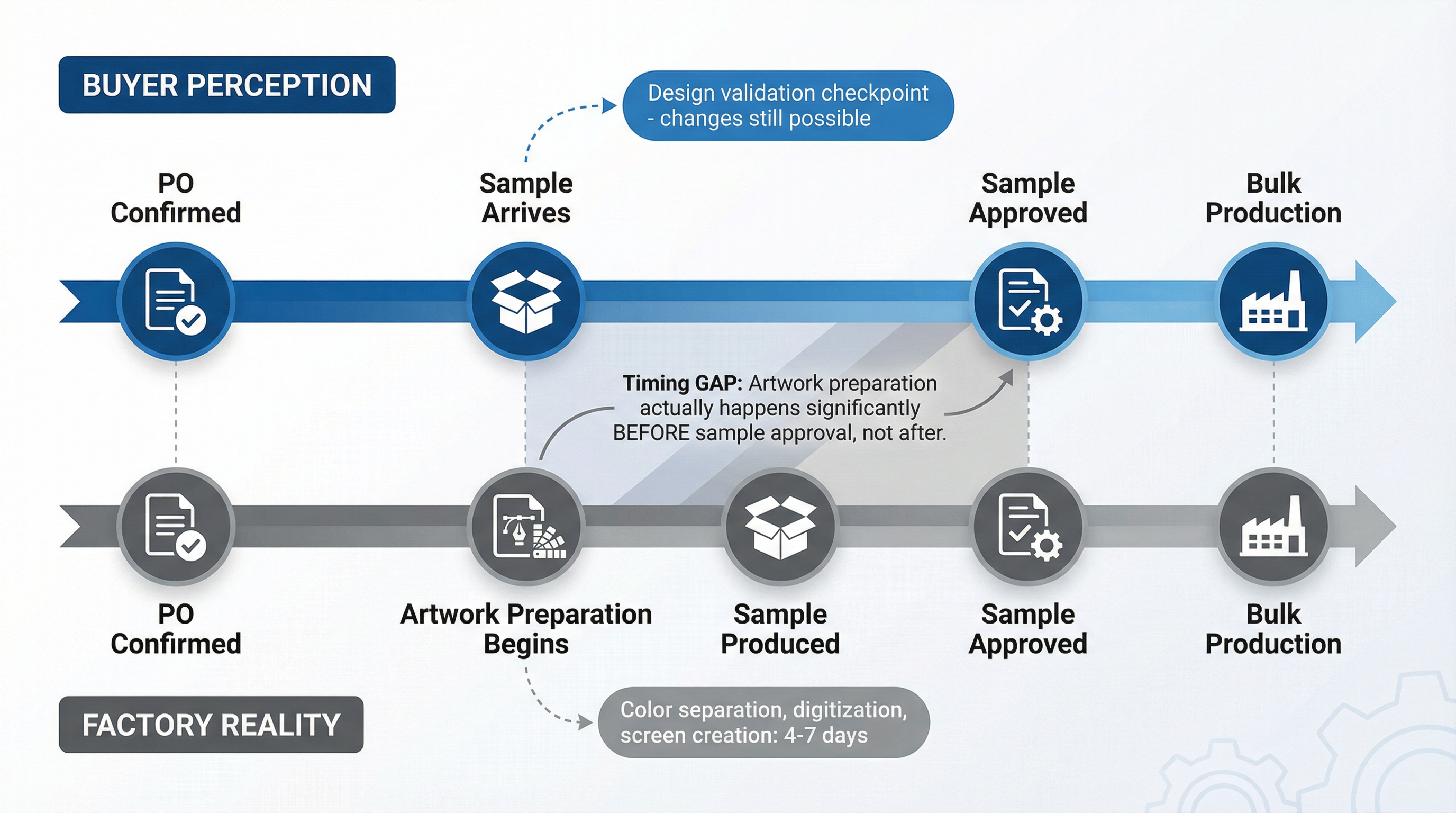

The Artwork Approval Timeline Trap: Why Production Lead Time Doesn't Start When You Place the Order

Factory project manager perspective: Procurement teams conflate 'order placement' with 'production start,' overlooking that artwork approval requires 1-2 weeks. Common file issues (RGB color mode, insufficient resolution, missing bleeds) trigger multiple revision cycles, each consuming 24-48 hours and compressing actual production time.

The Customs Clearance Documentation Timing Gap: Why Cargo Sits at Port for Two Weeks After Arrival

Compliance consultant perspective: Procurement teams treat customs clearance as an 'after-arrival' automatic process, overlooking that critical documents (HS codes, certificates of origin, material composition declarations) must be prepared before shipment. Incomplete or incorrect documentation causes sequential delays—each error adds 2-3 days, accumulating to 7-10 days of clearance delays.

The Freight Booking Decision Window Trap: Why Switching to Air After Production Delays Is Already Too Late

Logistics consultant perspective: Procurement teams assume shipping methods can be decided after production completes and that switching to air freight can recover time when delays emerge. In reality, freight booking must be finalized 5-7 days before cargo-ready dates. Missing this decision window causes costs to surge 3-5x and capacity may be fully booked, making switches impossible.

The Complete Guide to Customizing Reusable Bags for US Corporations

Navigate custom reusable bag procurement with confidence. Learn the 7-phase process, decision trade-offs, compliance requirements, and supplier vetting criteria for successful corporate orders.

The Specification Lock-In Cascade: Why Changing Your Mind About Bag Material After Sample Approval Costs 10x More

Corporate buyers treat customization specs as parallel decisions, but material, printing method, and artwork form a sequential dependency chain. Learn why post-approval changes trigger exponential cost escalation.

When Semi-Custom Takes Longer Than Full Custom: The 1,500-Unit Production Slot Problem

Orders in the 1,000-3,000 unit range with partial customization often face longer lead times than either decoration-only or fully custom runs. Understand why semi-custom specifications create scheduling challenges that buyers consistently underestimate.

The Printing Method Lock-In: Why Your Logo Artwork Becomes Irreversible Before You See the Sample

Corporate buyers often assume artwork can be refined after reviewing the sample, but artwork preparation—color separation, digitization, screen creation—happens before sample production. Understand why changing printing methods or logo details after the sample arrives triggers a 2-3 week delay cascade.

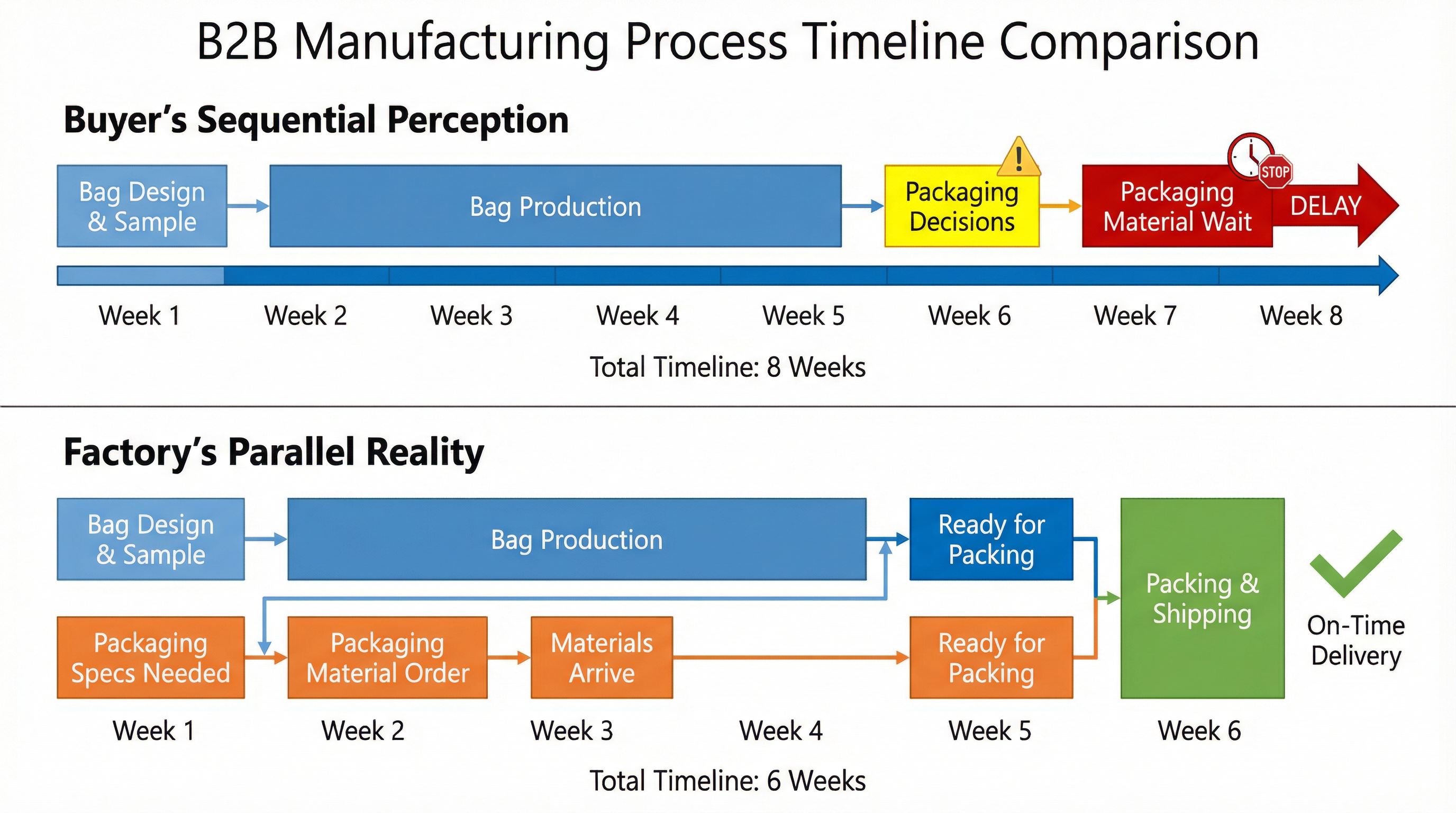

The Packaging Specification Parallel Track: Why Your Custom Bags Finish On Time But Can't Ship for Two More Weeks

Corporate buyers treat packaging as a post-production detail, but factories require packaging specifications—poly bags, cartons, labeling—at the same time bag production begins. This timing mismatch adds 2-4 weeks to delivery when packaging decisions are delayed until after bags are manufactured.

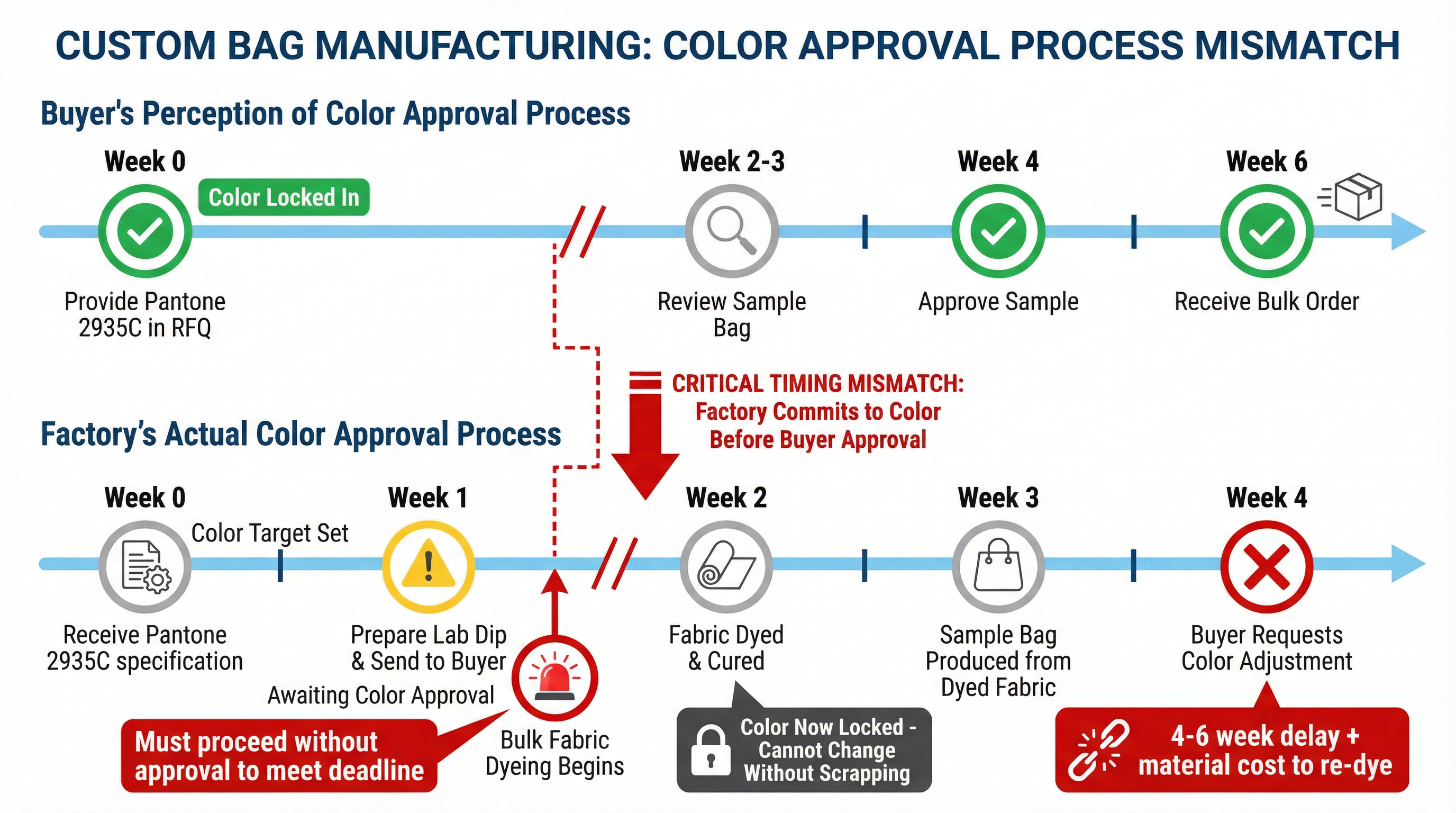

The Color Approval Cascade: Why Saying 'Match Pantone 2935C' Doesn't Lock In Your Bag's Actual Color

Corporate buyers assume providing a Pantone code locks in color, but actual color approval happens through lab dip review before bulk fabric dyeing. When buyers delay lab dip approval or treat sample approval as the color checkpoint, factories proceed with dyeing based on unapproved standards, creating a 4-6 week delay cascade when buyers request color adjustments after fabric is dyed.

The Specification Lock-In Cascade: Why Changing Your Mind About Bag Material After Sample Approval Costs More Than Two Weeks

Corporate buyers view sample approval as a decision checkpoint, but material procurement begins immediately after purchase order confirmation. This timing mismatch triggers cascading delays that add 4-6 weeks when specifications change post-sample.